We want to extend our heartfelt appreciation to all of you for your unwavering support and choice of the Tyvok Spider X1 Laser. The Spider X1 stands as a labor of love for us, a product that embodies the DIY spirit, and it's our hope that it brings you an abundance of joy and unleashes your creative potential.

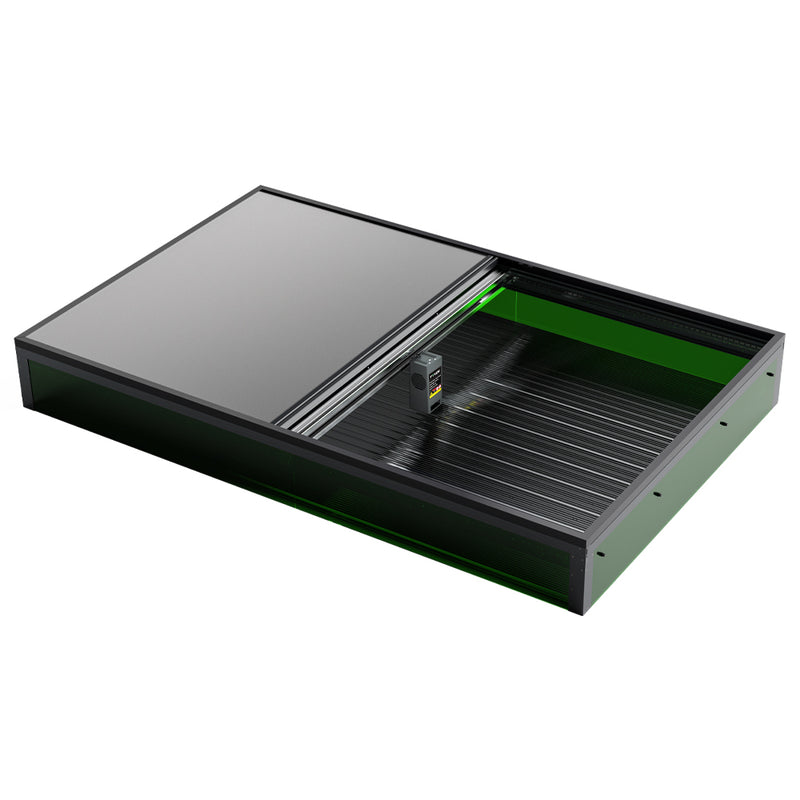

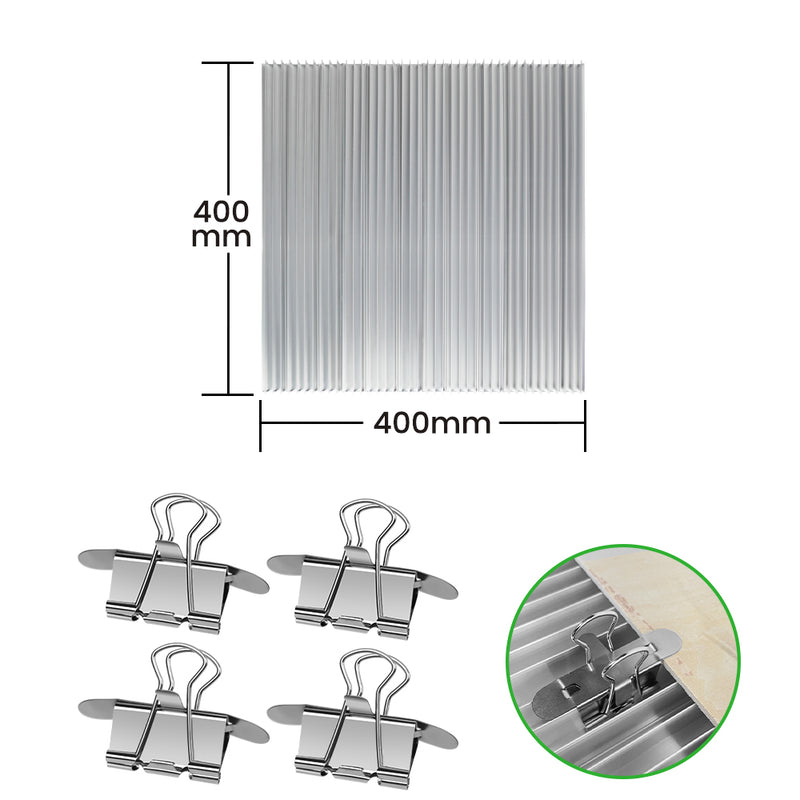

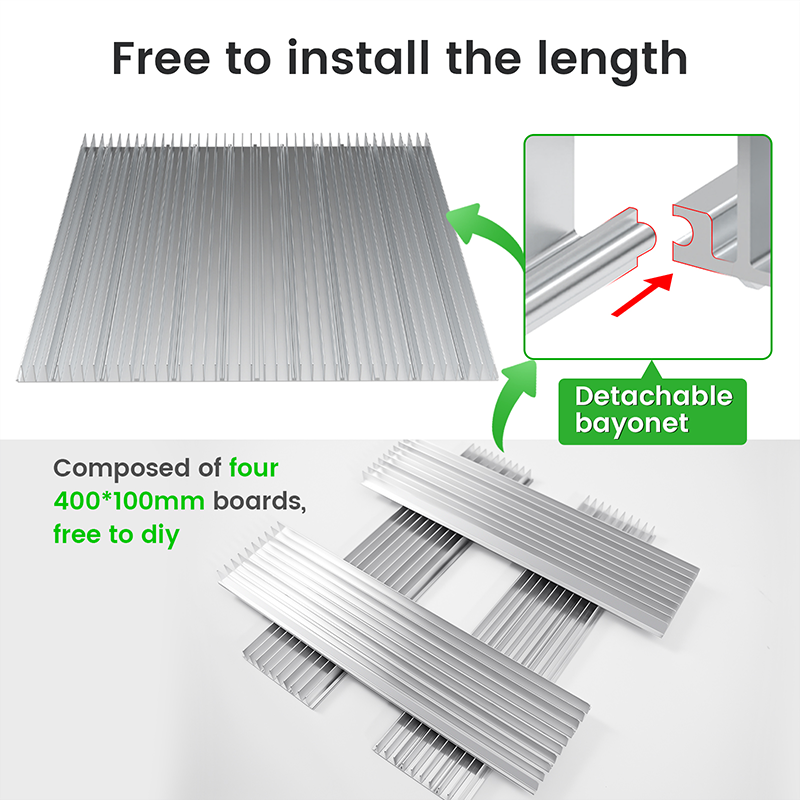

The design philosophy behind the X1 is nothing short of exceptional, with its primary focus on DIY craftsmanship. This extraordinary device allows you to seamlessly transition into roller mode, metamorphosing into an artist capable of both engraving and cutting in the blink of an eye. We hold a strong emphasis on precision cutting and have adopted a groundbreaking design that separates the framework from the engraving machine, effectively preserving cutting accuracy. What's more, the extendibility of the framework has been at the forefront, enabling you to achieve extended track cutting, especially suitable for large-scale projects and intricate item cutting and assembly, all with dimensions exceeding 400mm.

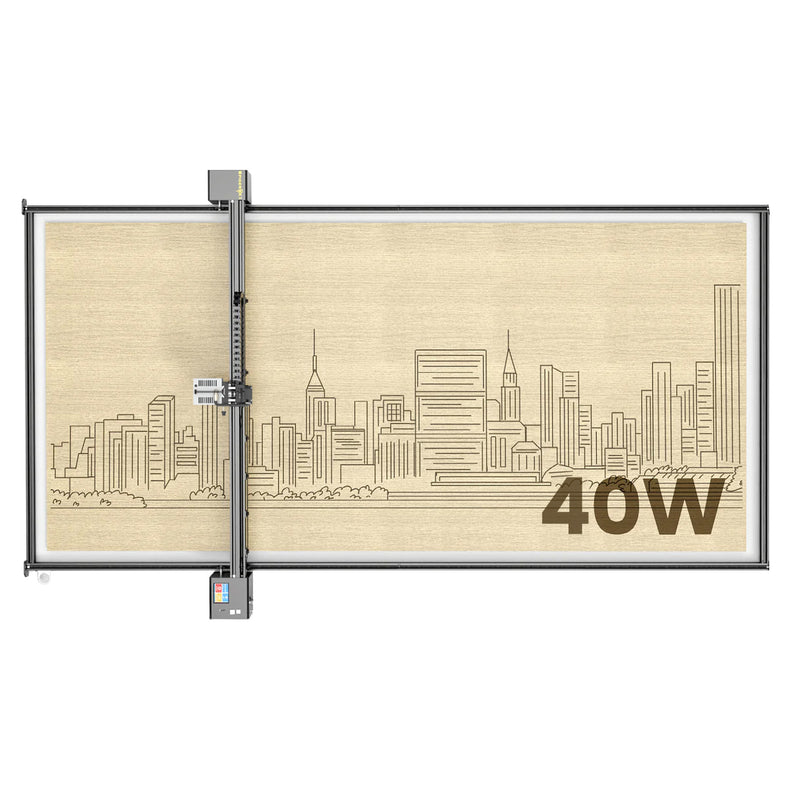

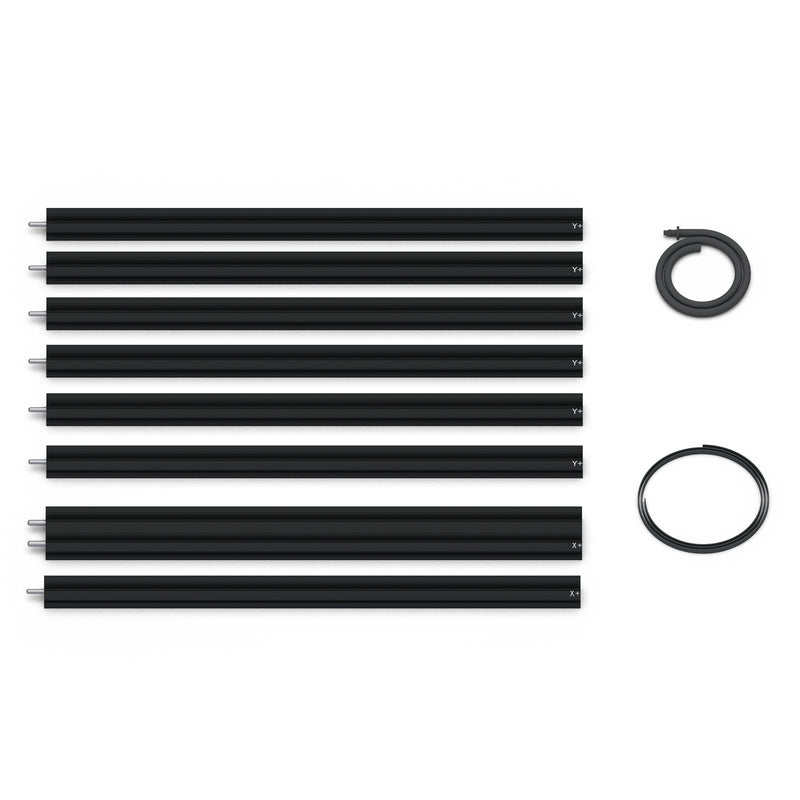

To cater to the diverse needs of our users, we've introduced enhanced extensibility for the X-axis. This feature empowers you to complete larger and longer engraving and cutting tasks in one go, considerably boosting productivity, reducing the hassle of material swaps, and optimizing material usage.

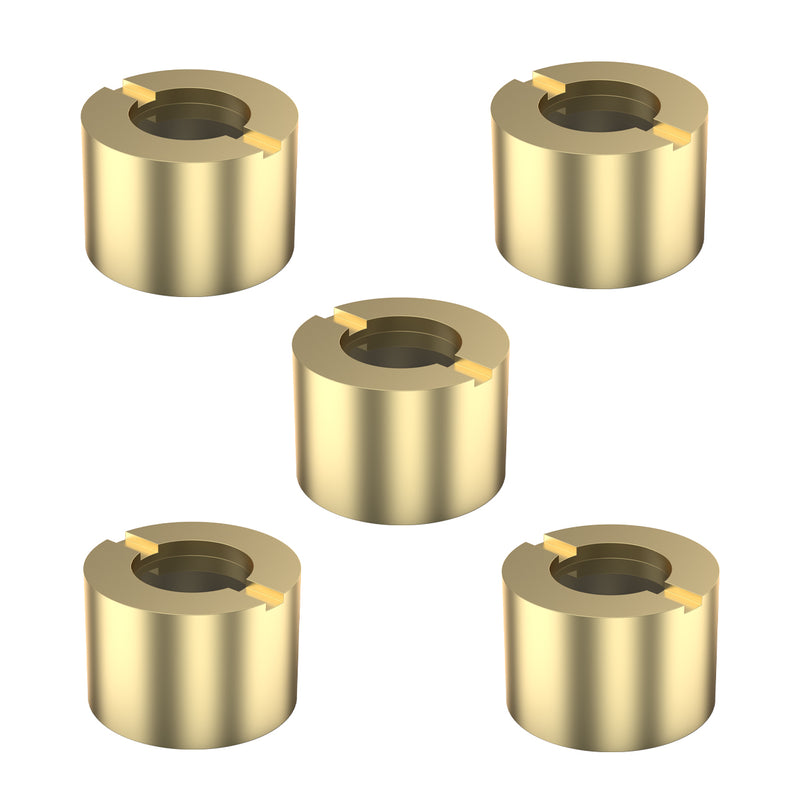

We're attuned to the DIY desires of our user base, which is why we've incorporated standard aluminum profiles for the framework. This ensures that users can personalize larger and longer tracks to meet their specific needs. However, it does present a challenge as standard profiles come with inherent limitations in precision. To address this, each product undergoes meticulous calibration before leaving our factory to ensure that the framework and tracks are perfectly aligned with your requirements. We've thoughtfully included adjustable knobs at the guide rails to provide added flexibility, even though this may involve a bit more work for first-time users.

Given the continuous extendibility of the Y-axis, there's no fixed starting point. While this offers users tremendous freedom, newcomers may require some time to acquaint themselves with this feature. Consequently, we recommend users start in roller mode, utilizing a TF card to import files and conducting basic engraving to ensure the smooth operation of the machine. Subsequently, we suggest a gradual exploration of tasks such as frame installation, precision cutting, and framework extension.

The true value of the Spider X1 emerges when you're consistently producing more works of art. To aid users in leveraging the product to its full potential, we've meticulously prepared a comprehensive suite of resources, including user manuals, online documentation like product guides, Wikis, and troubleshooting guides, all designed to assist you in overcoming any challenges you may encounter. What's more, we've been tirelessly creating YouTube tutorials and practical case studies. Every case you see is a real-world example, complete with step-by-step guides, parameter settings, and downloadable project files by Spidermake. All these resources are freely available, and we eagerly await your feedback and suggestions, which will undoubtedly propel our product's continuous improvement.

Simultaneously, we are actively engaged in compatibility testing and ongoing collaboration with LightBurn software and the LaserGRBL free community to enhance the user experience further.

As we approach Halloween and Christmas, our shared aspiration is to embark on a journey of creativity and exploration. Dream Big and Make it Happen.