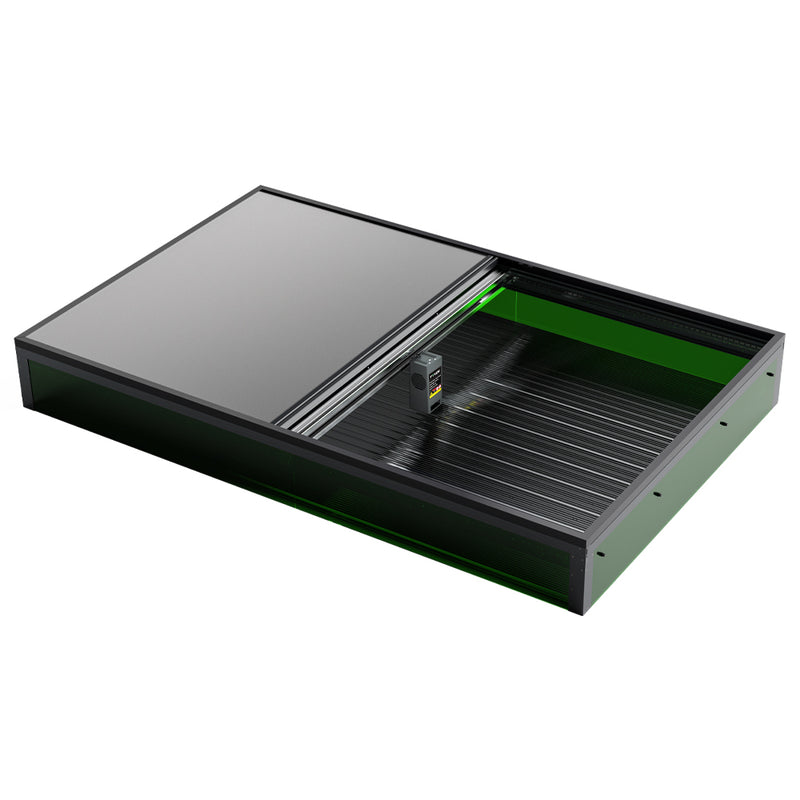

This blog aims to provide a practical guide for those interested in creating large furniture using Spider X1 laser engraver. From choosing the right materials to mastering the engraving process, we'll cover essential steps and considerations to help you embark on your furniture-making journey.

1.Selecting Suitable Materials:

Choosing the right materials is crucial for successful laser engraving on large furniture. Here are some popular options:

- Wood: Opt for high-quality hardwoods like oak, walnut, or maple, known for their durability and work ability.

- Plywood: Plywood is an affordable and versatile material that can be laser engraved with impressive results.

- MDF (Medium-Density Fiberboard): MDF is an excellent choice for large furniture due to its uniform density and smooth surface.

2. Designing for Laser Engraving:

Before diving into the engraving process, it's essential to prepare your designs accordingly. Here are a few key considerations:

- Vector Graphics: Use design software to create vector graphics, as they can be easily scaled without losing quality.

- Design Dimensions: Ensure your design matches the dimensions of the furniture piece to achieve a balanced and cohesive look.

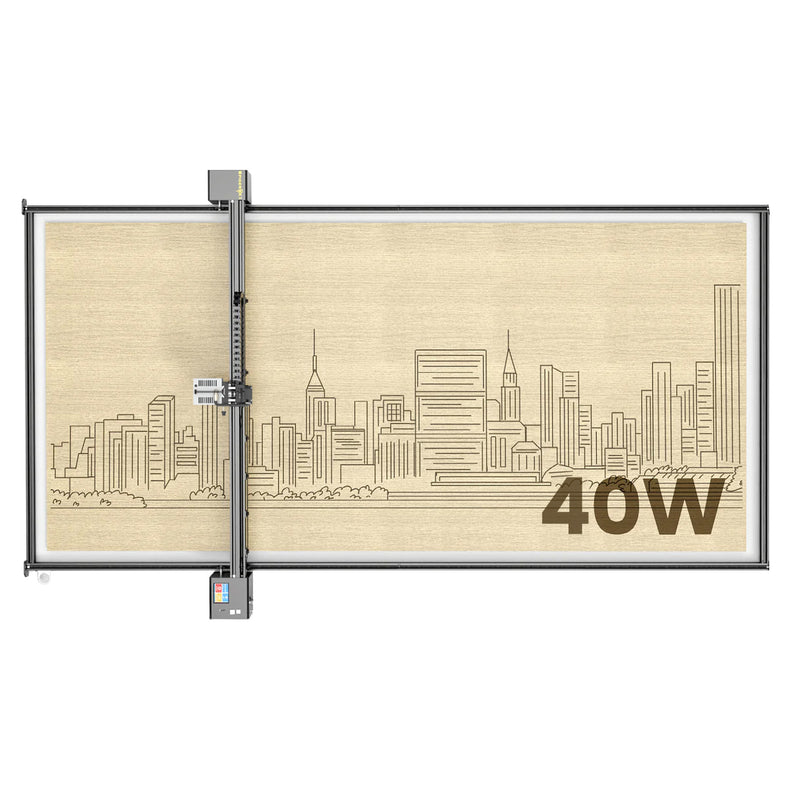

3. Laser Engraving Techniques:

Mastering the laser engraving process is key to achieving desired results. Here are some techniques to keep in mind:

- Testing and Calibration: Conduct test engravings on scrap material to fine-tune laser settings, including power, speed, and focus.

- Depth Control: Adjust the laser power and speed to control the depth of the engraving, ensuring consistent and desired results.

- Multiple Passes: For deeper engravings, consider multiple passes with lower power settings to avoid excessive burning or charring.

4. Safety Precautions:

Working with laser engravers requires strict adherence to safety guidelines. Keep the following precautions in mind:

- Protective Gear: Wear appropriate safety glasses to shield your eyes from laser radiation. Gloves and a respirator might be necessary when working with certain materials.

- Ventilation: Ensure proper ventilation in your workspace to dissipate fumes and minimize the accumulation of potentially hazardous particles.

5. Finishing Touches:

Once the engraving process is complete, it's time to add the finishing touches to your large furniture piece:

- Sanding and Smoothing: Use sandpaper or a sanding block to smooth the engraved surface and remove any residue or rough edges.

- Finishing Options: Consider applying a suitable finish, such as varnish or oil, to enhance the appearance and protect the engraved surface.

- Assembly and Installation: Follow standard furniture assembly procedures to complete your large furniture piece, ensuring stability and durability