As a jewelry designer, you know the magic of transforming a sketch into a wearable story—especially when it involves intricate details on stainless steel or sterling silver. But let’s face it: traditional engraving tools often feel like holding you back. Smudged lines on silver, faint marks on stainless steel, and endless hours spent polishing away mistakes? That’s not the way creativity should flow. Enter the blue laser engraver(like TyvokS1)—engineered to deliver 0.01mm precision where it matters most, so your designs don’t just meet expectations—they redefine them.

The Jewelry Designer’s Dilemma: Why Metals Make Engraving So Tough

Imagine this: A client commissions a pair of custom sterling silver rings with their anniversary coordinates engraved inside the band—in elegant cursive. You reach for your go-to tools, only to hit these roadblocks:

- Stainless steel’s glossy finish reflects standard laser beams, leaving logos patchy and uneven.

- Silver’s soft surface warps under heat, creating burnt edges that turn a quick task into a day-long polish marathon.

- Tiny details (think 0.3mm letters) get lost in translation, forcing you to simplify designs or risk disappointing clients.

These aren’t just annoyances—they’re barriers to creating the high-end, personalized pieces your brand is known for. What if you could bypass the frustration and bring your boldest ideas to life, exactly as you envisioned?

The Blue Laser Difference: 3 Features That Redefine Metal Engraving

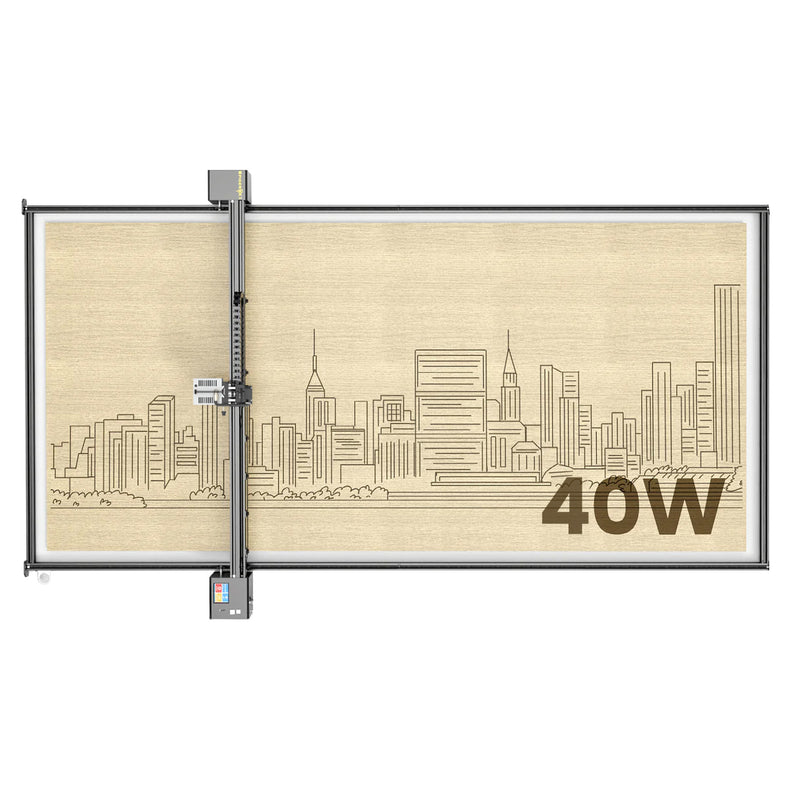

Designed exclusively for jewelry designers, blue laser engravers leverage 450nm wavelength technology to tackle the unique challenges of stainless steel and silver. Here’s how they turn technical limits into creative opportunities:

1. 0.01mm Precision: Details So Sharp, They Stand Up to Microscopy

Blue lasers focus energy into an incredibly tight 0.05mm beam spot (half the size of standard lasers), enabling engravings as fine as 0.1mm tall—perfect for:

- Ring interiors: Etch 0.2mm handwritten names onto 2mm-wide silver bands, crisp and readable under 10x magnification.

-

Pendant masterpieces: Carve intricate star maps onto 1mm² stainless steel surfaces, with 0.08mm line spacing that captures every celestial detail.

Real talk: A Parisian jewelry atelier used a blue laser to engrave a client’s fingerprint onto a silver locket. The result? A 150% spike in custom orders, driven by details so intimate, they became a signature selling point.

2. Metal-Ready Technology: No Prep, No Compromises, Just Results

Ditch the messy sprays and sanding steps. Blue lasers come with an adaptive energy algorithm that auto-adjusts for metal properties:

- Stainless steel: Emits rapid, high-frequency pulses (20kHz) to penetrate reflective surfaces, ensuring even energy distribution and consistent engraving depth—no more patchy logos.

-

Sterling silver: Uses “cold engraving” (surface temp rise <5°C) to prevent oxidation, preserving the metal’s natural luster. Engrave directly on polished silver, then go straight to plating—no rework, no hassle.

Pro tip: Save 30% prep time per project by skipping pre-treatments. Your workflow (and clients) will thank you.

3. Small-Batch Perfection: Turn Concepts into Catalog-Worthy Pieces Faster

Jewelry thrives on uniqueness, and blue lasers excel at bringing one-of-a-kind ideas to life:

- Single-piece precision: Engrave tiny serial numbers on 1mm² stainless steel tags with zero setup delay—ideal for limited editions or bespoke commissions.

- Designer-friendly software: Import AI or CorelDRAW files directly, preserving every curve of your original sketch. A Brooklyn-based designer cut her prototype time from 3 days to 6 hours by engraving a vintage family crest onto a silver bracelet—no design compromises, no lost details.

Blue Laser vs. Traditional: The Numbers That Matter

| Feature | Traditional Lasers | Blue Laser Engravers | What It Means for You |

|---|---|---|---|

| Beam Spot Size | 0.1mm+ (fuzzy, uneven lines) | 0.05mm (sharp, defined edges) | No more “close enough”—details are crisp |

| Metal Prep Work | Required (sprays, sanding) | None (works on polished surfaces) | Save hours on prep for every project |

| Heat Damage Risk | High (50°C+ surface temp) | Virtually zero (<5°C temp rise) | Engrave delicate silver without worrying about discoloration |

Case Study:

A luxury jewelry brand in Milan faced a challenge: creating custom engagement rings with microscopic engravings of handwritten vows inside 1.5mm-wide platinum bands. Traditional laser systems couldn’t handle the tight space without charring, while manual engraving was too slow and inconsistent.

A luxury jewelry brand in Milan faced a challenge: creating custom engagement rings with microscopic engravings of handwritten vows inside 1.5mm-wide platinum bands. Traditional laser systems couldn’t handle the tight space without charring, while manual engraving was too slow and inconsistent.

By adopting the TyvokS1, they achieved:

- 0.01mm precision on curved surfaces using the machine’s dynamic focus adjustment, which automatically adapts to ring band geometry.

- Zero oxidation on silver and platinum thanks to the “cold engraving” feature, eliminating post-engraving polishing.

- 200% faster production for limited-edition runs, with pre-programmed metal preset modes that switch seamlessly between stainless steel, silver, and gold.

The result? A 30% increase in high-margin custom orders and rave reviews from clients who valued the “invisible yet unforgettable” details.

How to Choose the Right Blue Laser Engraver for Your Studio

Not all blue lasers are created equal. Look for these jewelry-specific features to ensure precision and peace of mind:

- Dynamic Surface Tracking: Automatically adjusts focus for curved surfaces (like ring bands) to maintain consistent depth—no more uneven engravings.

- Metal Preset Modes: Pre-programmed settings for stainless steel, sterling silver, and gold—just select your material and go, no trial-and-error.

- Integrated Fume Extraction: Safely removes metal vapor during engraving, keeping your workspace clean and compliant with safety standards.

Ready to Turn Micro-Details into Major Impact?

The right tool doesn’t just solve problems—it unlocks possibilities. With a blue laser engraver, you can:

- Command premium prices: Deliver museum-worthy details that justify higher budgets.

- Expand your material menu: Work with stainless steel, silver, and even gold with confidence, knowing every engraving will be flawless.

- Focus on creativity: Spend less time fixing mistakes and more time designing—because your talent deserves a tool that keeps up with your vision.

Your jewelry shouldn’t just be worn—it should be remembered. Upgrade to blue laser engraving, where every detail is a testament to your artistry.