The Problem: Why Cold Weather is Dangerous for CO₂ Lasers

Winter is tough on traditional CO₂ laser cutters, especially those relying on water cooling:

-

Frozen coolant can crack glass laser tubes or damage chillers.

-

Chiller startup failures often happen below ~10 °C (50 °F).

-

Condensation from rapid temperature changes can corrode power supplies and optics.

If your laser is sitting in a cold garage or workshop, these risks are very real.

What Laser Owners Typically Do

Across forums and maker communities, users share their winter “survival hacks”:

-

Using RV/Marine antifreeze mixed with distilled water.

-

Running a space heater to keep the garage above freezing.

-

Installing aquarium heaters or pumps to keep water circulating.

-

Draining coolant completely when the machine is not in use.

These methods can work, but they are inconvenient, inconsistent, and prone to failure.

General Winterization Checklist for CO₂ Lasers

| Step | What to Do | Why It Matters |

|---|---|---|

| 1. Monitor temperatures | Keep a thermometer near the machine. | Act before temps drop below 4 °C / 40 °F. |

| 2. Drain when unused | Empty coolant if not running for days. | Prevents cracked tubes/chillers. |

| 3. Use RV-safe antifreeze | 50/50 with distilled water. | Protects down to -31 °C. |

| 4. Keep coolant moving | Aquarium heater or low-power pump. | Avoids freezing and thermal shock. |

| 5. Add insulation or heat | Heater or insulated box. | Reduces temperature swings. |

| 6. Flush in spring | Replace with pure distilled water. | Keeps optics and tubes efficient. |

Why Tyvok K1 Solves This Natively

Unlike traditional CO₂ cutters, Tyvok K1 was engineered to be indoor-friendly from day one.

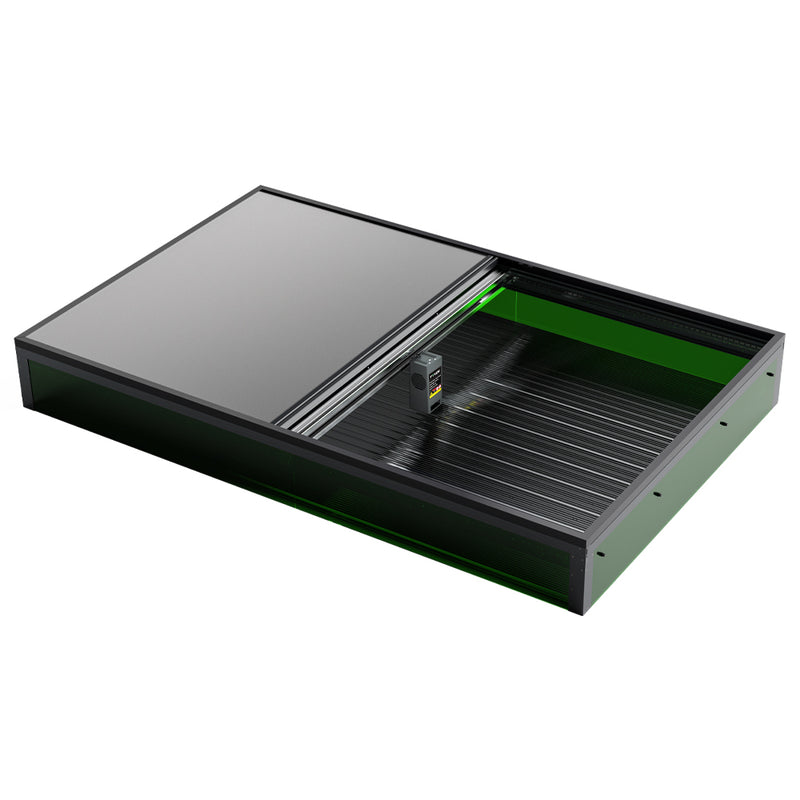

Indoor-Friendly Design

-

Compact footprint: Fits comfortably in home studios and workshops.

-

Max height ≤ 600 mm: Even as a complete unit, K1 is designed under 600 mm, so it can pass through standard doors, stairways, and elevators.

-

Flexible placement: Can be positioned as a whole unit or in separated modules, making it easier to adapt to limited spaces.

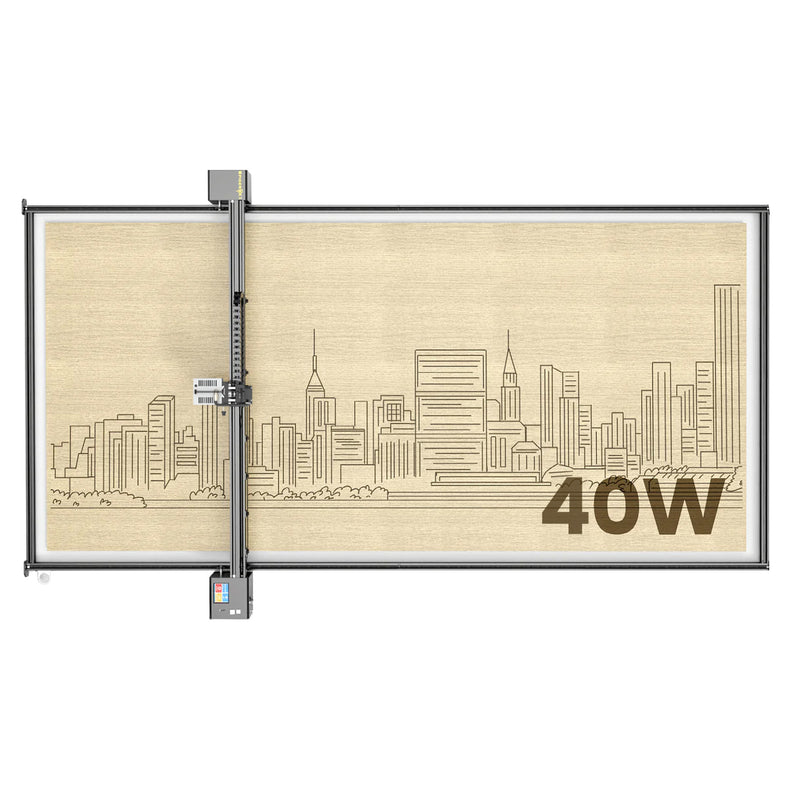

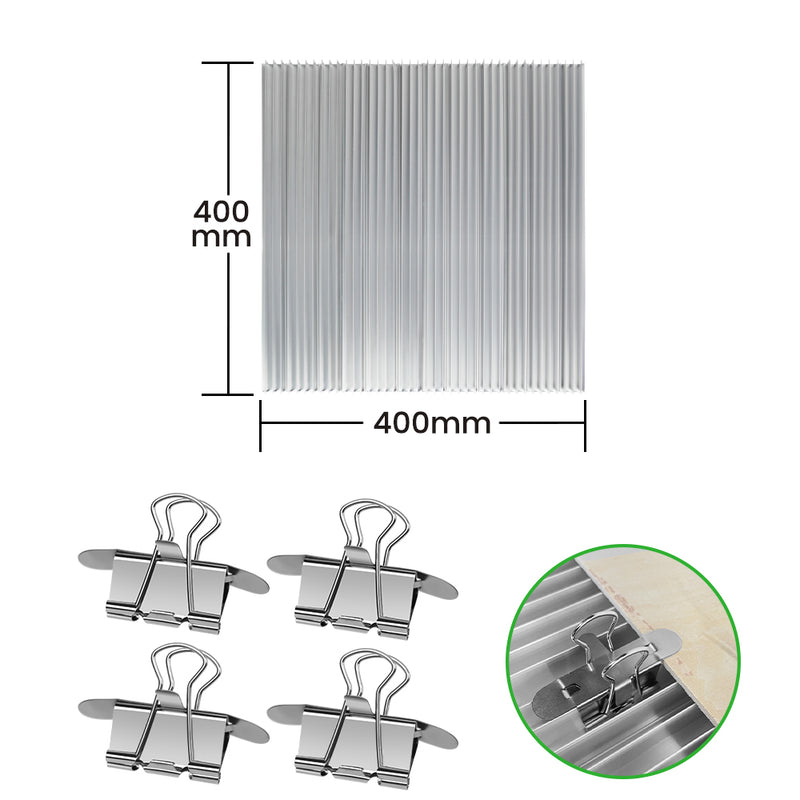

Higher Frame Utilization

-

~90% X-axis utilization, compared to ~50% in traditional CO₂ lasers.

-

This means: for the same working area, K1’s outer frame is much smaller and lighter, saving space while keeping industrial-grade performance.

Z-Axis & Bottom Clearance

-

45 mm auto-leveling: One-touch autofocus for quick material changes.

-

Up to 220 mm bottom clearance: Instead of relying on heavy, manual bottom plate lifting (typical in traditional CO₂), K1 leaves extended clearance for thicker or 3D materials.

-

Future-ready: Reserved height ensures your K1 remains upgradeable and long-lasting.

Cooling, Simplified

-

Integrated cooling by default: Plug-and-play, no external chiller required for normal use.

-

Optional external chiller: For high-duty, long-duration projects, simply connect a chiller and switch modes.

-

Dual-mode flexibility: Choose what works best at any time.

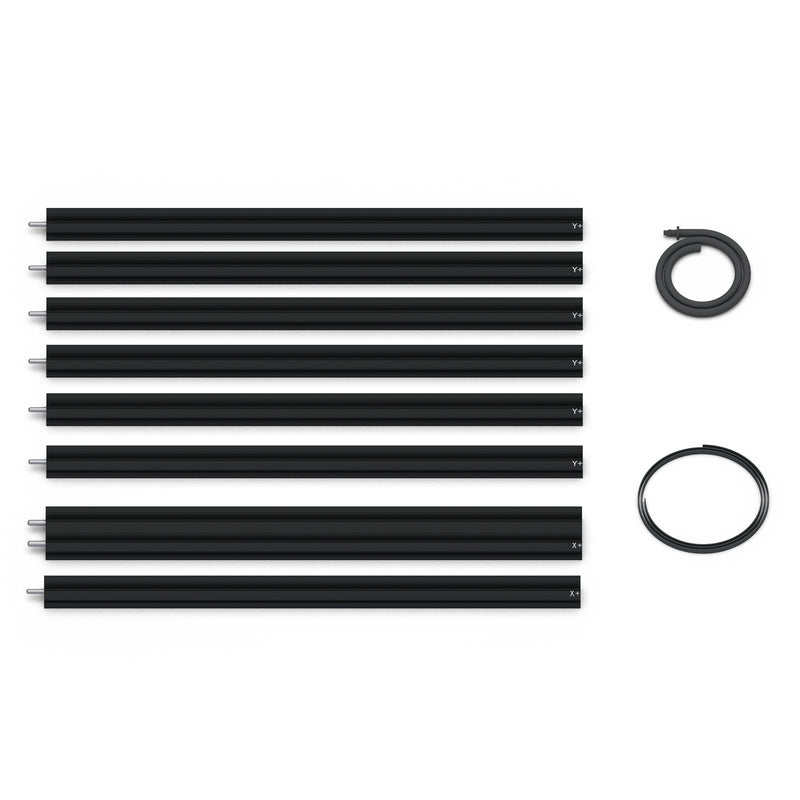

Future Expandability

-

Direct X/Y axis upgrades: Expand your working area and power capacity by swapping or extending axes.

-

K1 is not just a machine — it’s a platform built to grow with your needs.

Common Questions

Can a CO₂ laser be used indoors?

Yes, provided you have proper exhaust and filtration. Tyvok K1 was designed specifically to fit into normal rooms, with compact size, quiet operation, and safe ducting options.

How does Tyvok K1 handle thicker materials?

With 45 mm auto-leveling and up to 220 mm bottom clearance, K1 supports both standard sheet materials and taller 3D objects without hassle.

What makes K1 easier to move indoors?

Unlike bulky traditional CO₂ lasers, K1’s maximum height is under 600 mm, meaning it can pass through doors, stairways, and elevators. You can bring industrial-grade cutting power into your home or small studio.

Is Tyvok K1 upgradeable?

Yes. The platform is designed for direct X/Y axis upgrades, meaning your machine can scale as your projects and business grow.

Conclusion

Traditional CO₂ lasers in winter often require draining water, mixing antifreeze, or heating your garage just to keep the machine alive.

Tyvok K1 eliminates those headaches: with its compact design, ≤600 mm indoor-friendly height, ~90% frame utilization, 45 mm auto-leveling, 220 mm extended bottom clearance, integrated cooling, and future expandability, it’s the world’s first CO₂ laser platform truly built for indoor use and long-term growth.

Call to Action

Ready to bring CO₂ power indoors, without winter worries?

👉 [Pre-Order Tyvok K1: k1.tyvok.com