Simplifying Precision for Engineers, Makers, and Businesses Alike

When it comes to CO₂ laser machines, most users know the pain points: leveling platforms, manual adjustments, and the endless struggle to maintain consistent focus across a large work area. With the Tyvok K1, we approached this problem differently. Instead of forcing users to adapt to the constraints of traditional machines, we reimagined how focus and platform design could work together—and the result is a much simpler, more reliable solution.

Traditional CO₂ Lasers: Platform-Dependent Focusing

In a conventional CO₂ laser cutter, the laser tube and cutting head are separated. The laser beam is reflected two or more times before reaching the cutting lens. This architecture fixes the cutting head at one height, which means focusing must be done by moving the entire work platform up and down.

-

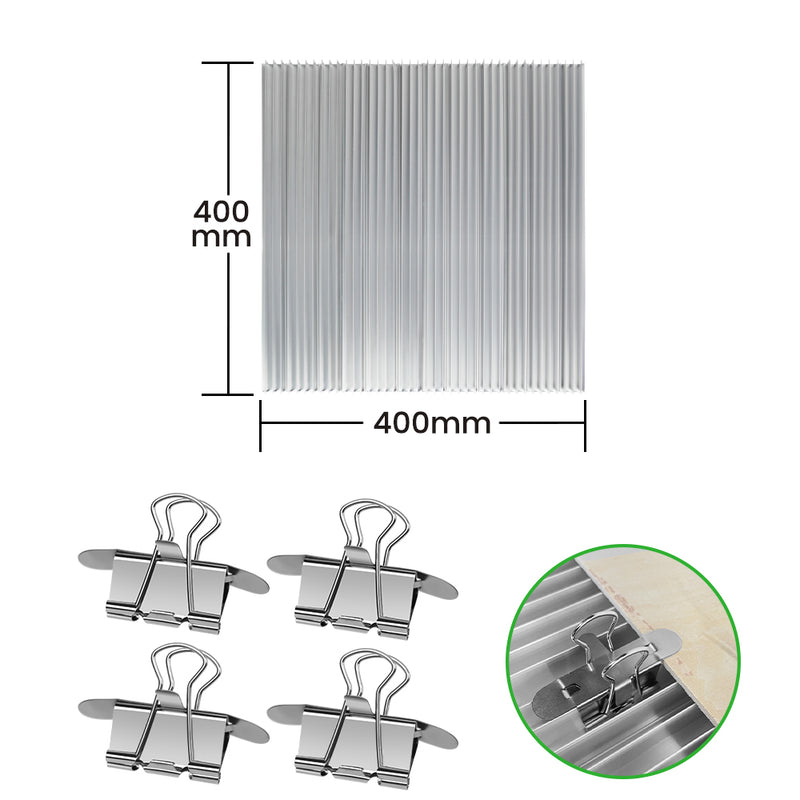

Precision leveling required: The platform’s four corners must remain perfectly aligned. Any tilt means one side of the material is in focus while the other is not.

-

Difficult with larger machines: As the working area grows, gravity, weight, and structural flex make maintaining a perfectly flat platform much harder.

-

Manual or semi-automatic adjustments: Entry-level machines rely on hand-cranks and screws; higher-end machines may include motorized platforms or autofocus probes. Still, as the bed size increases, keeping everything flat and synchronized becomes a constant battle.

Image suggestion:

Side-by-side diagram showing a traditional CO₂ setup: separated tube and head, mirrors, and a moving platform used for focus adjustment.

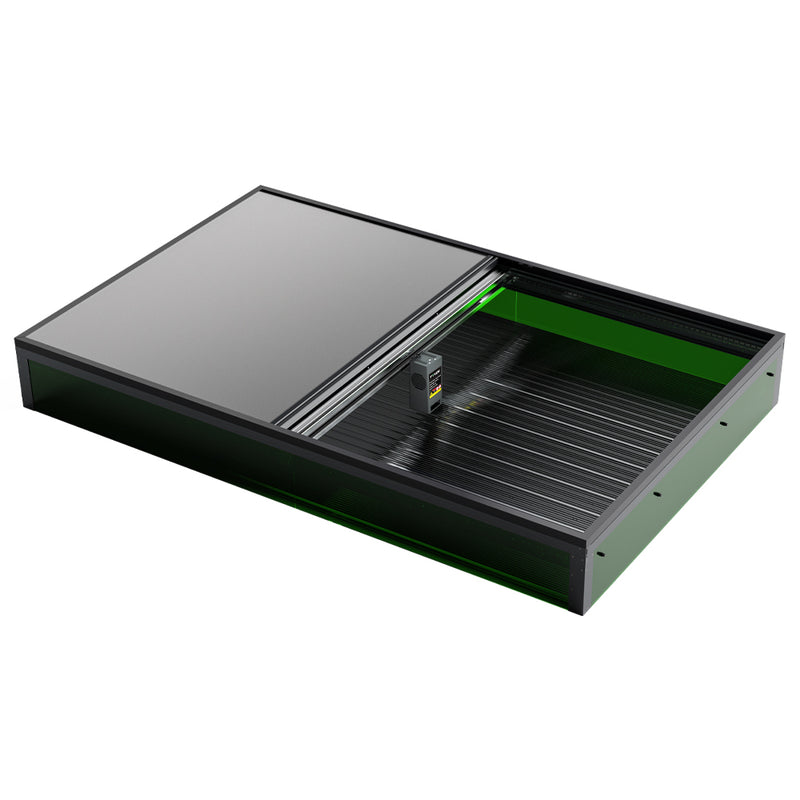

Tyvok K1: Integrated Laser Head and Smart Z-Axis

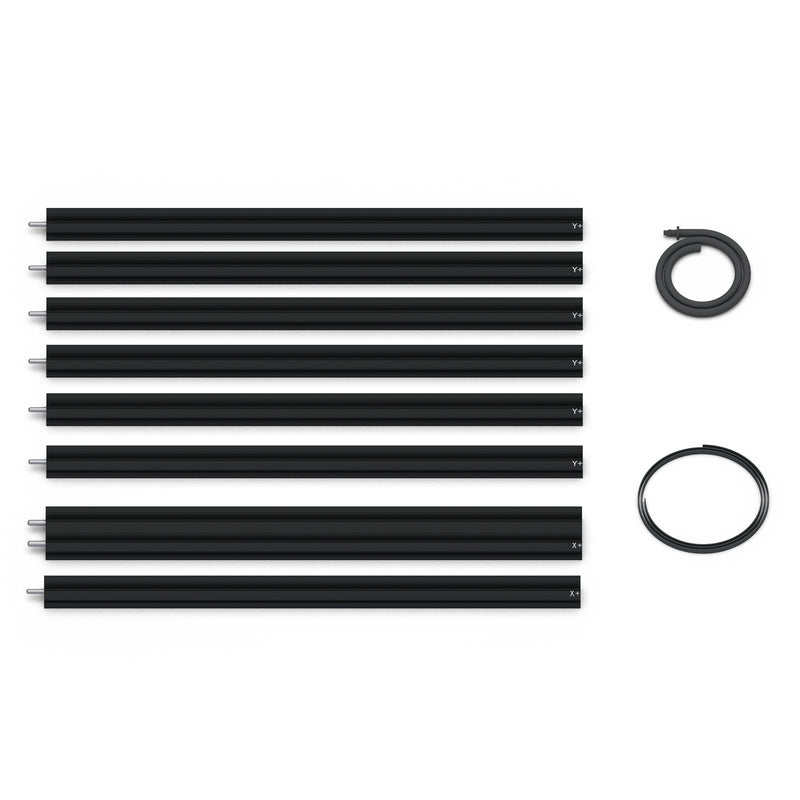

The Tyvok K1 takes a radically different approach. Instead of separating the tube and optics, we integrate the laser tube and laser head into a single fixed module, factory-aligned and mounted on the X-axis beam. The result: no mirror alignment for the user, no complicated beam path maintenance.

-

Focus by moving the head, not the platform: The K1 adjusts focus by raising or lowering the laser head assembly (about 45 mm of travel), not the heavy work table.

-

Stable fixed platform: The honeycomb or blade bed remains fixed in place. Once leveled at installation, it stays flat and consistent over time.

-

Automatic focusing: With built-in sensors, K1 automatically measures the material surface and sets the correct focal point, eliminating manual guesswork.

This design makes the machine lighter, faster, and more user-friendly. Instead of constant adjustments, users can focus on the creative work.

Image suggestion:

Diagram of the K1 head module moving vertically for focus, with a fixed stable platform underneath.

Open Platform for Unlimited Material Flexibility

Another key differentiator is K1’s open platform design:

-

Tall objects: For thicker materials or cylindrical objects, simply remove or open the bottom and place the item underneath. Unlike traditional enclosed CO₂ machines, K1 isn’t limited by Z-height.

-

Long materials: The front and rear of the platform are open, allowing pass-through cutting of oversized boards or panels. This makes it ideal for furniture panels, signage, or any long-format material.

-

Convenient feeding: Continuous feeding becomes practical—you can move a long workpiece through the machine in stages without complex jigs.

Image suggestion:

Photo mockup of K1 cutting a long wood panel passing through front-to-back, compared with a closed-box CO₂ machine that requires window lifting.

Extended Benefits Beyond Focusing

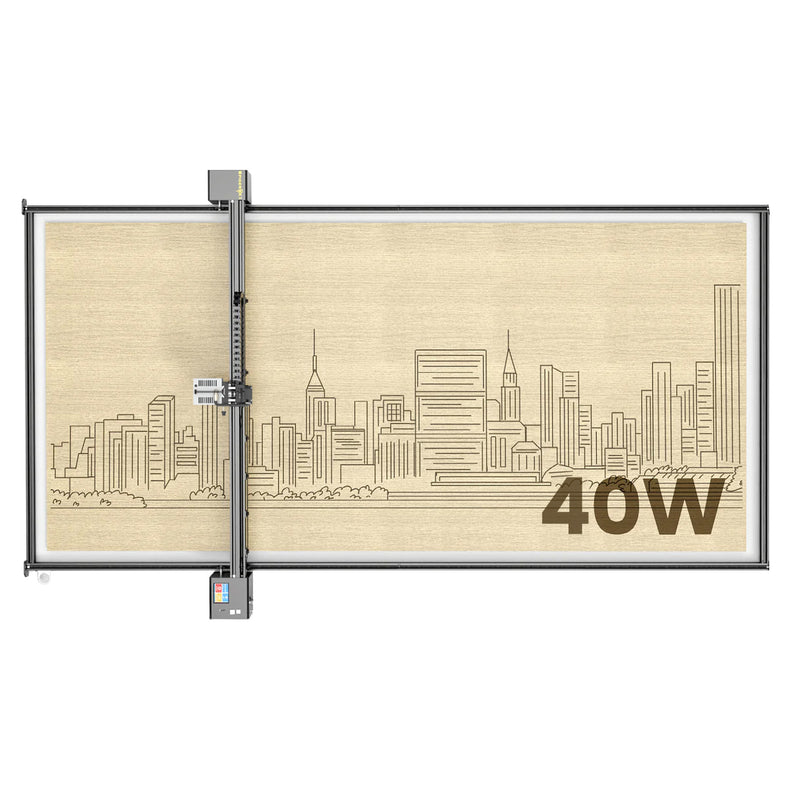

The K1 platform doesn’t just solve focusing—it also raises the bar in performance:

-

Power and depth: 100 W CO₂ tube capable of cutting up to 20 mm materials in a single pass.

-

Precision: ±0.05 mm repeatability across the entire working area.

-

Speed: Engraving speeds up to 1000 mm/s for both high productivity and fine detail.

-

Software ecosystem: Fully compatible with LightBurn, RDWorks, and Tyvok Studio, giving both professionals and beginners a smooth workflow.

-

Clean and safe: Dual-channel exhaust with smart airflow switching ensures smoke is efficiently removed during engraving and cutting.

Real-World Scenarios

-

Thick Wood Carving: A 50 mm hardwood slab can be placed beneath the K1 by opening the bottom, then engraved layer by layer with automated focus adjustments.

-

Cylindrical Objects: A large wine bottle or stainless tumbler can be engraved using a rotary attachment placed under the K1 head—no need to worry about machine clearance.

-

Oversized Panels: A 2 m decorative board can be processed in sections, with seamless alignment thanks to K1’s automatic focusing and stable platform.

These are real use cases where K1 users can work faster and more creatively than with traditional CO₂ platforms.

Conclusion: A Smarter Way to Work

By integrating the laser tube and optics into one module, and by moving the head instead of the platform, Tyvok K1 eliminates the headaches of leveling and focusing. Add in an open design, automatic focus, and industrial-grade performance, and you have a CO₂ laser platform built not just for today’s tasks—but for the future of flexible, creative manufacturing.

Image suggestion (closing):

A comparison chart summarizing:

Traditional CO₂ → Moving platform, manual leveling, enclosed box, limited material size.

Tyvok K1 → Moving head, auto focus, open pass-through, supports tall/long objects.