The design philosophy behind Spider X1S reflects a profound consideration for user experience, stemming from the holistic approach of the X1 series. We have strategically optimized and innovated in several key areas.

X1 Series Design Philosophy:

The X1 series prioritizes large dimensions, scalability, standardization, and ease of DIY upgrades. The goal is to empower users to source materials locally and effortlessly install their equipment. To achieve this, we addressed the challenge of separating the X and Y axes, allowing independent usage and expansion—thus forming the X1 series solution. Despite introducing a more extensive Bill of Materials in the production process, we remain committed to delivering a relatively comprehensive user experience. Our vision is for users to seamlessly embark on basic carving using the scroll mode upon receiving the X1 series. In standard frame mode, an experience akin to traditional frame machines is achieved. With increasing demands and extended cutting times, users can extend the Y-axis to meet larger format requirements. When facing the need for substantial area cutting and carving, expanding the X-axis becomes a straightforward process. This design not only caters to a broader spectrum of intricate carving and cutting but also fulfills diverse real-life needs, including small-batch production.

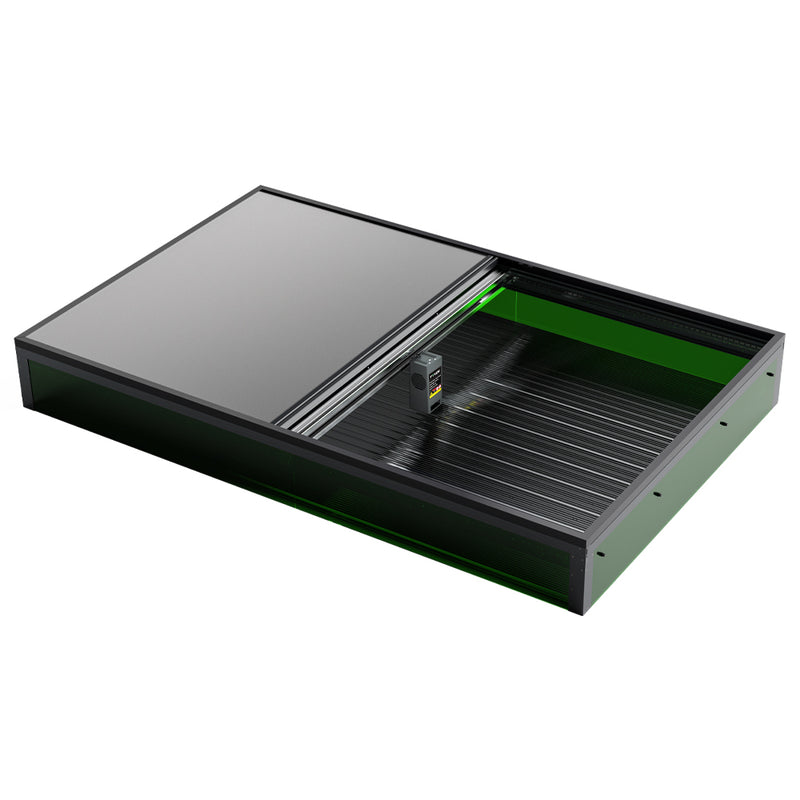

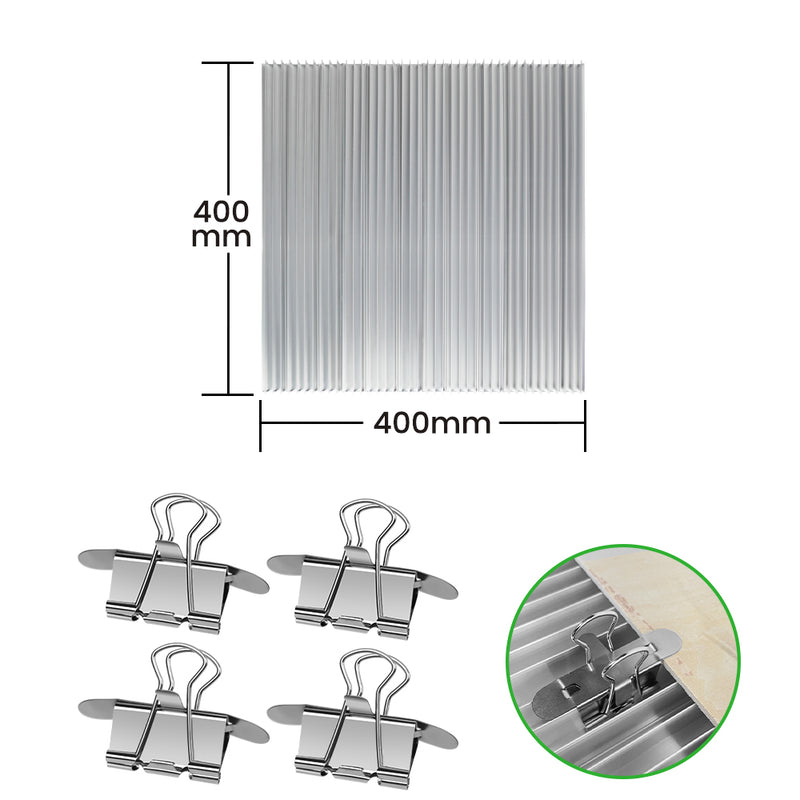

Frame Enhancement:

Building upon the overall design of the X1, the X1S introduces a shift from a 3-sided frame to a more stable 4-sided frame, addressing user familiarity with frame machines. This upgrade enhances stability while minimizing the internal support structure's intrusion into the workspace. Stability is further augmented by the addition of anti-slip pads at the base, significantly increasing friction and preventing slippage. A visual comparison of the X1 and X1S mainframes illustrates the structural differences.

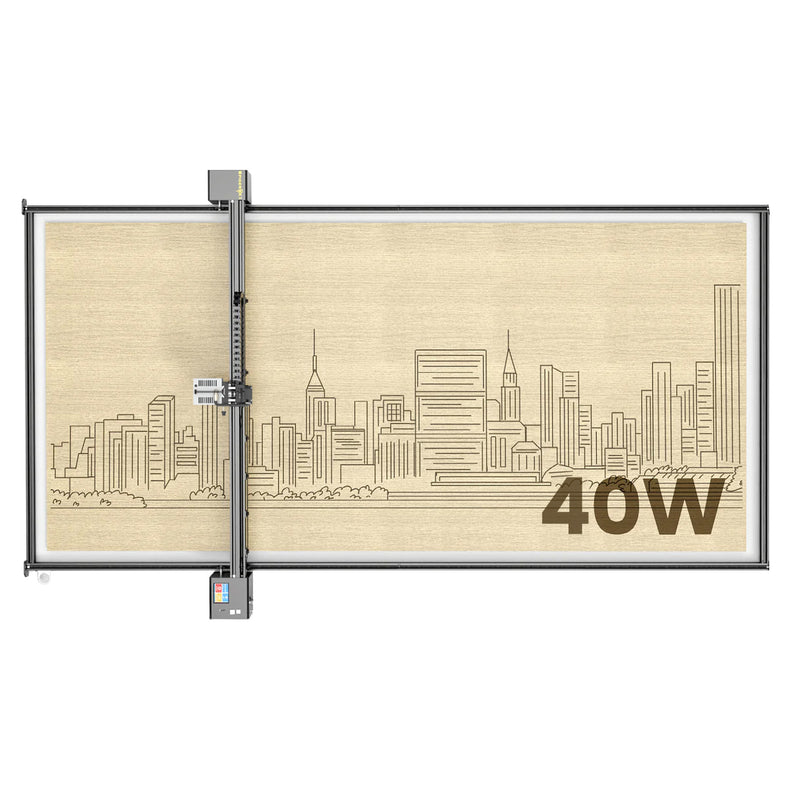

Optimized Physical Origin:

Acknowledging the user habits of frame machine enthusiasts, the X1S incorporates additional sensors and technological optimizations to enhance the physical origin feature. In frame mode, users can emulate the basic operation habits of conventional frame machines. Considering the 800*2000mm large format mode, we strategically position the origin closer to the user's operational direction, minimizing interference with small to medium-sized objects. In extended mode, this design significantly facilitates user operations, aligning with the consistent positioning of the origin in large fiber laser machines. Visual references showcasing the exact position of the origin are provided.

Enhanced Safety and Stability:

Safety has always been a paramount concern in laser engraving and cutting. The X1S addresses safety during elevation by incorporating a higher-precision gyroscope. Extensive testing has been conducted, demonstrating successful elevations ranging from 10 to 45 degrees. A 15-degree elevation proves sufficient for user requirements. Following elevation, the safety trigger halts laser operations, and the shifted track renders it unsuitable for continued carving or cutting, necessitating a restart. This comprehensive approach ensures both safety and stability. Visual references displaying the inclination and gyroscope effectiveness are included.

Improved Air Assistance Convenience:

Air assistance plays a crucial role in laser cutting, prompting continuous optimization efforts. The X1 comes standard with an air assistance connector, requiring only external connection for operation. To enhance the convenience of air assistance, the X1S mainframe introduces a direct power interface for air assistance, eliminating the need for additional power sources and reducing plug and cable usage. To cater to varied cutting and engraving needs, an adjustable airway knob has been incorporated, allowing users to easily regulate air volume. Additionally, the one-piece design of the X1S minimizes excessive wiring. Testing confirms that the X1S can directly support air assistance, reducing cable and air assistance interface lengths. Visual references showcasing the integrated air assistance and machine compatibility are provided.

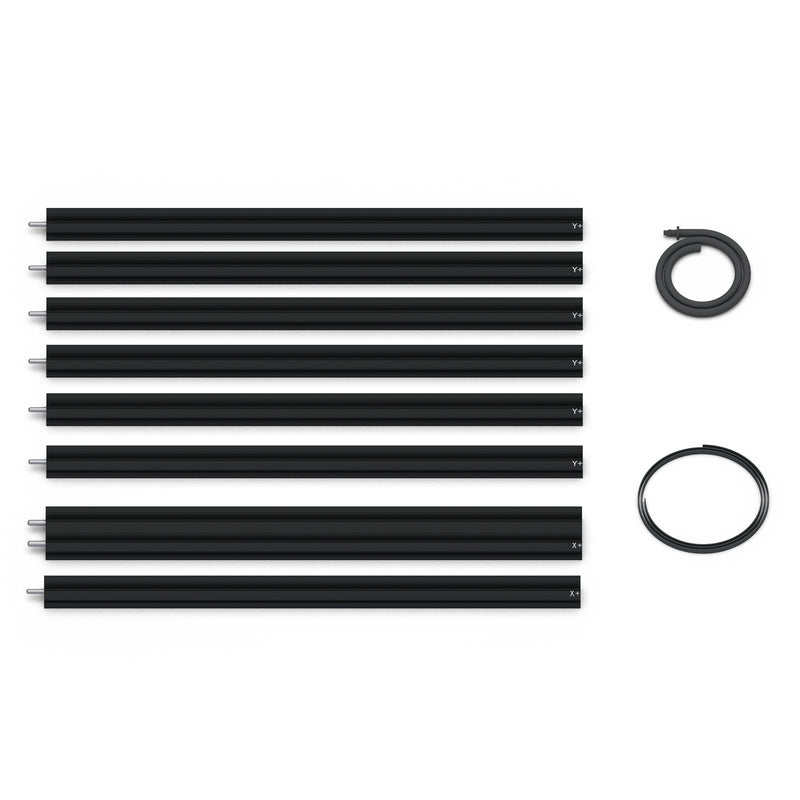

Unified X-Axis Design:

In pursuit of maximum stability and prevention of loosening during transport, the X1S adopts an integrated profile design for the X-axis. This design minimizes the risk of loosening during transportation, enabling users to open the machine and use it without extensive adjustments. The integrated design is equally applicable for user expansions of the X-axis, ensuring heightened stability.

Given the constraints of this format, not all intricate details can be presented. However, we pledge to continuously release more information. Through our collaborative efforts with users, we believe the Spider X1S will deliver an even more outstanding experience, empowering you and your colleagues to utilize the product more effectively and achieve exceptional creative results.