The demand for CO₂ laser engravers has grown rapidly among makers, workshops, and small businesses. Whether you are cutting acrylic signs, engraving wood, or working with glass and leather, understanding how to choose the right machine is critical. In this guide, we’ll cover key topics such as air assist systems, refurbished vs. new machines, material performance, UV laser applications, and introduce why the Tyvok K1 100W CO₂ Laser Engraver stands out as one of the best laser cutters in 2025.

1. Why Air Assist Matters for CO₂ Laser Cutting

-

Benefits of air assist:

-

Cleaner edges, reduced burn marks

-

Faster cutting speeds

-

Extended lens and nozzle lifespan

-

-

Setup recommendations:

-

Hobby users: a small air pump is usually sufficient

-

Professional workshops: at least a 60–80 gallon compressor with a dryer is ideal

-

👉 Tyvok K1 Advantage: The K1 features a dual-airflow design with smart switching between engraving and cutting modes. This ensures sharp edges on wood and acrylic, and prevents charring during glass engraving.

2. Should You Buy New or Refurbished?

-

New machines: Higher reliability, full warranty, latest upgrades

-

Refurbished machines: 20–30% cheaper, often recalibrated by the factory

-

When to find them: Some brands release refurbished units around August each year

👉 Tyvok K1 Advantage: Instead of worrying about second-hand risks, the K1 offers global warranty support and modular assembly design, making upgrades and servicing much easier.

3. How Different Materials Perform with a CO₂ Laser

-

Wood:

-

Walnut: clean engraving but lower contrast

-

White Oak: strong contrast but leaves more residue

-

Poplar: cuts easily, great for entry-level users

-

-

Acrylic: Clear, smooth edges, ideal for signage

-

Glass: Requires fine control, works best with CO₂ engraving

-

Leather: Produces a premium look for DIY bags, wallets, and crafts

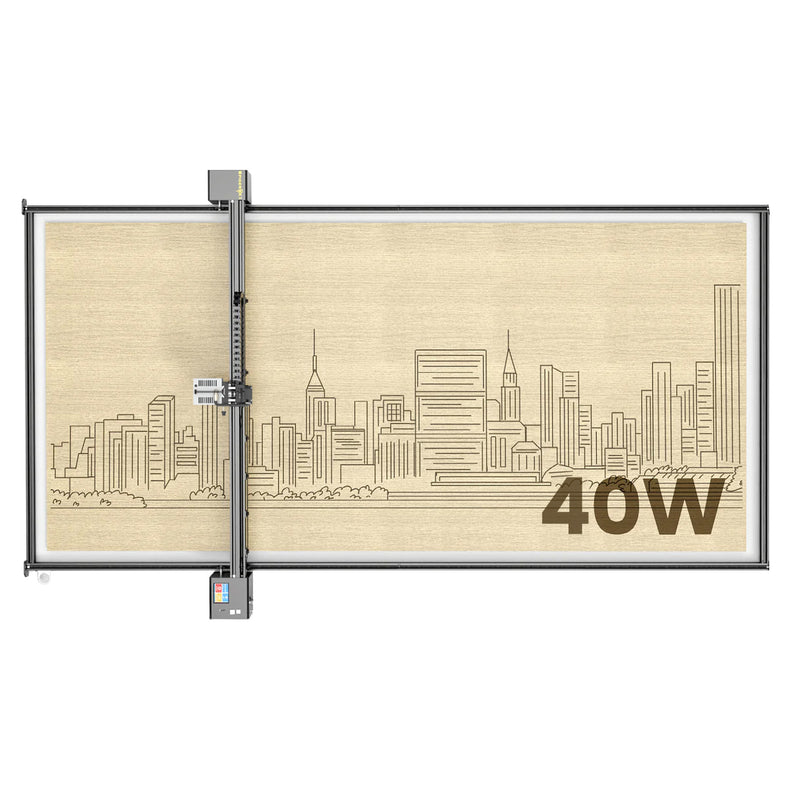

👉 Tyvok K1 Advantage: Equipped with a 100W Yongli CO₂ laser tube, the K1 easily cuts 10–15mm acrylic and supports multi-material engraving (wood, leather, glass, plastics) — making it perfect for both hobbyists and businesses.

4. The Role of UV Lasers and When to Use Them

-

Strengths: Non-thermal marking, great for plastics, glass, and medical devices

-

Applications: Phone cases, precision parts, electronics

-

Limitations: Slower processing and more complex setup

👉 Tyvok K1 Comparison: If your primary goal is large-format cutting and thick materials, a CO₂ engraver like the K1 is far more efficient than a UV laser.

5. Pro Tips to Boost Productivity with a CO₂ Laser

-

Use jigs for repeat engraving tasks

-

Keep the nozzle clean for consistent air flow

-

Invest in a UPS backup system to prevent unfinished jobs

-

Automate reminders to turn on air assist and exhaust before cutting

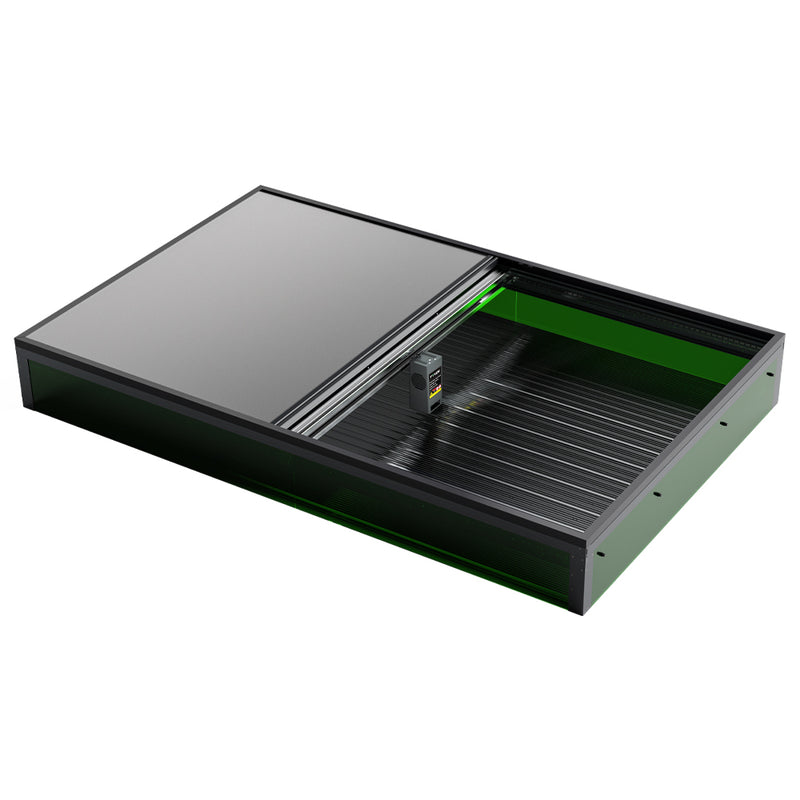

👉 Tyvok K1 Advantage: Fully compatible with RDworks, LightBurn, and Tyvok Studio, plus Wi-Fi connectivity for direct file transfer. With auto-focus and dual exhaust system, the K1 is built for efficiency.

Frequently Asked Questions (FAQ)

Q1: How thick can the Tyvok K1 cut?

A: Up to 15mm acrylic in a single pass with clean, polished edges.

Q2: What makes Tyvok K1 different from other CO₂ engravers?

A: The K1 combines 100W power, modular assembly, dual exhaust, global warranty, and industrial software support, setting it apart from typical DIY machines.

Q3: Does the K1 support remote service?

A: Yes. Tyvok offers remote diagnostics and worldwide after-sales support, ensuring users get professional help anywhere.

Conclusion: Why Tyvok K1 is the Best CO₂ Laser Engraver in 2025

Choosing the right CO₂ laser engraver comes down to performance, reliability, and software compatibility. With its 100W power, modular design, global warranty, dual air assist, and LightBurn compatibility, the Tyvok K1 Series is built to be one of the best CO₂ laser cutters of 2025.

👉 Learn more and reserve yours now at k1.tyvok.com.