Got a message the other day from a fellow maker who’s been pushing the limits of what laser cutting can do—and honestly, it fired me up. He’s been playing around with stacking wood like paper, making glowing lightboxes out of acrylic, even mixing in some 3D-printed parts for more texture and depth. Pretty cool, right?

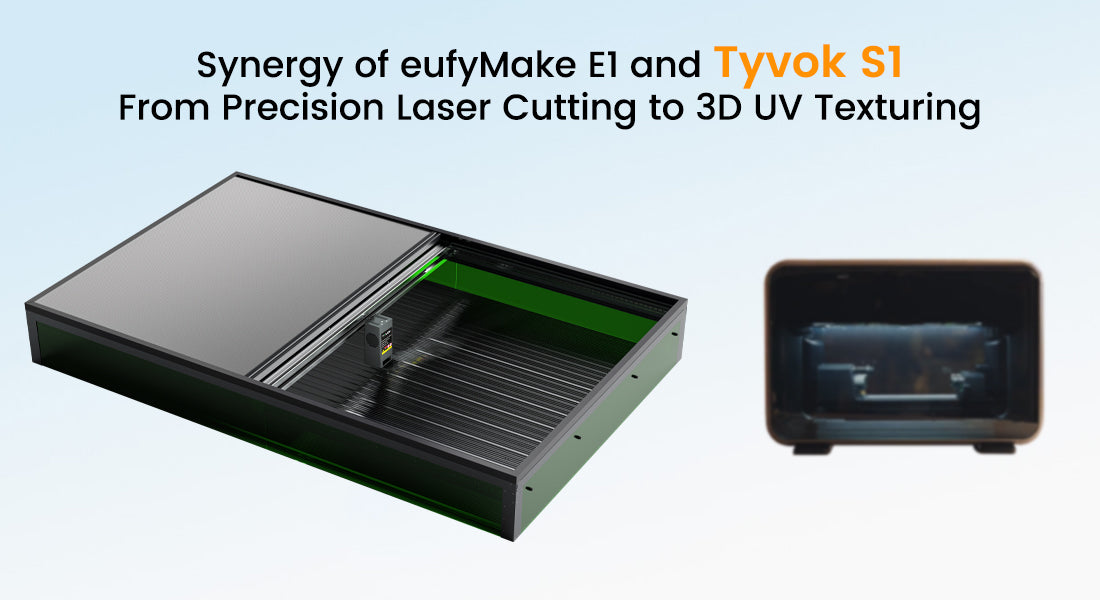

But here’s the kicker—he just backed that new eufyMake E1 UV printer on Kickstarter (you’ve probably seen it blowing up online), and he’s planning to pair it with his Tyvok laser machine to create these crazy-detailed, full-color, textured designs straight on top of engraved surfaces. Think: translucent prints on clear acrylic, wood that feels hand-painted, and layered builds with serious dimension.

It’s got me thinking: what happens when you combine a laser that can cut and carve with a printer that can print color and texture? You get a whole new creative workflow—structure first, then texture. That’s where the magic is.

And the numbers back it up. The E1 is the world’s first personal 3D-texture UV printer, and it just crushed its Kickstarter goal—raising over $12 million in a single day. Pair that with the Tyvok S1’s massive 4×8 ft work area and 60W diode laser, and you’ve got a dream setup for makers, designers, and small businesses who want their work to pop off the table—literally.

Executive Summary

The eufyMake E1 is the world’s first personal 3D-texture UV printer, raising $12,375,213—over 2,400% of its $500 K goal—in 24 hours on Kickstarter.

Its Amass3D™ technology builds up to 5 mm of relief with six-color UV inks and AI-powered auto-positioning.

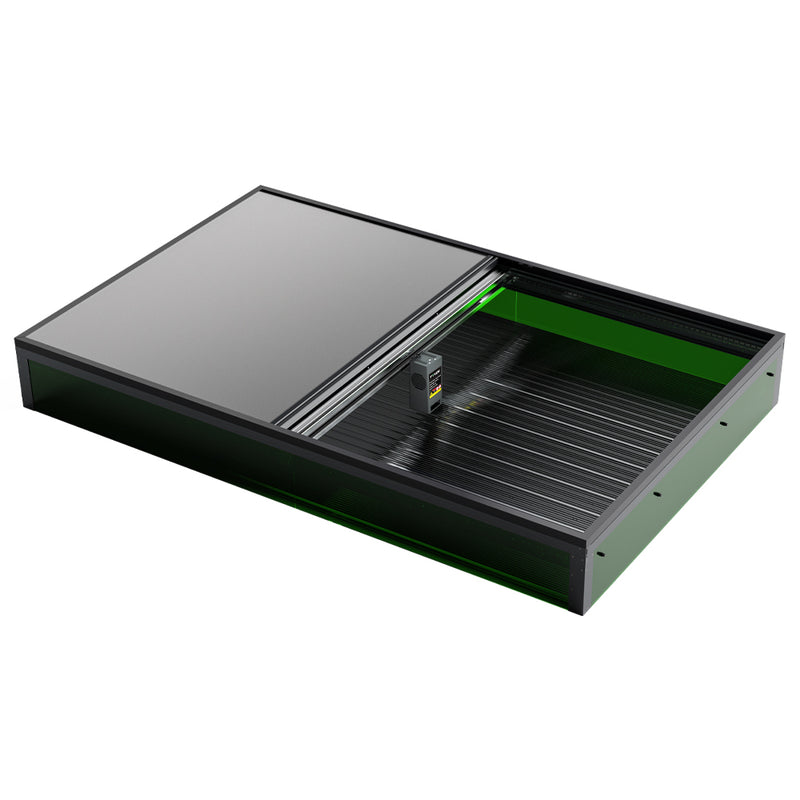

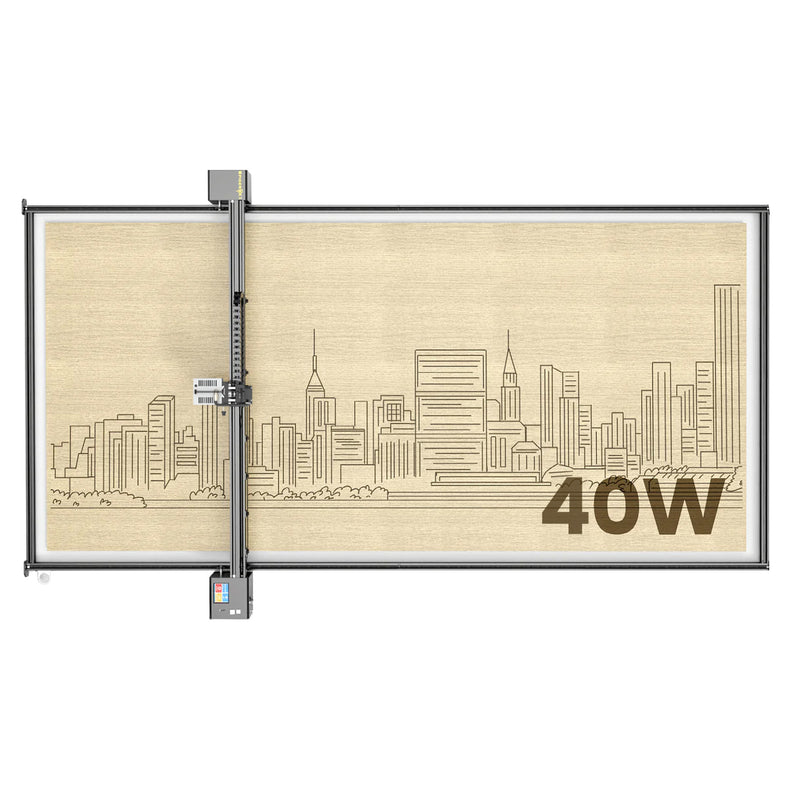

The Tyvok S1 large-format laser engraver features a 60 W adjustable diode laser, a fully enclosed design with automatic exhaust, and an extendable 1250 × 2440 mm bed—perfect for vector cutting, drill relief, and high-precision engraving.

Together, they form a streamlined workflow: laser-cut precise contours, then UV-print rich 3D textures for vibrant, tactile creations.

1. eufyMake E1: Personal 3D-Texture UV Printer

1.1 Amass3D™ Layering Technology

E1 uses UV-curable inks that instantly solidify, allowing users to stack material up to 5 mm thick in customized relief patterns—ideal for simulating brush strokes, wood grain, or embossed effects.

1.2 Six-Color ColorMaestro™ System

Featuring CMYK, white, and gloss inks, E1 achieves 100% color accuracy across wood, metal, glass, acrylic, and more substrates, unlocking new possibilities for product mockups, signage, and art prints.

1.3 AI-Powered Auto-Positioning

Dual-laser dot matrices and a high-resolution SnapShot™ camera provide “zero-error” alignment by scanning cut contours and adjusting print coordinates automatically—no manual calibration needed.

1.4 Modular 3-in-1 Design

E1 integrates flatbed printing, DTF laminating, and an optional rotary module on a 330 × 420 mm bed, expanding to cylindrical objects like mugs and tumblers.

2. Record-Shattering Kickstarter Launch

On April 29, 2025, eufyMake E1 went live on Kickstarter and reached $12.38 million in pledges—2,475% of its $500 K goal—in under 24 hours. Over 27,000 backers have already joined, making it one of the most successful personal-tech campaigns of the year.

3. Tyvok S1: Professional-Grade Laser Engraver & Cutter

3.1 High-Power Diode Laser

The Spider S1 supports 60 W diode lasers (down-selectable to 40 W or 20 W), delivering both rapid raster engraving and vector cutting on wood, acrylic, leather, and more.

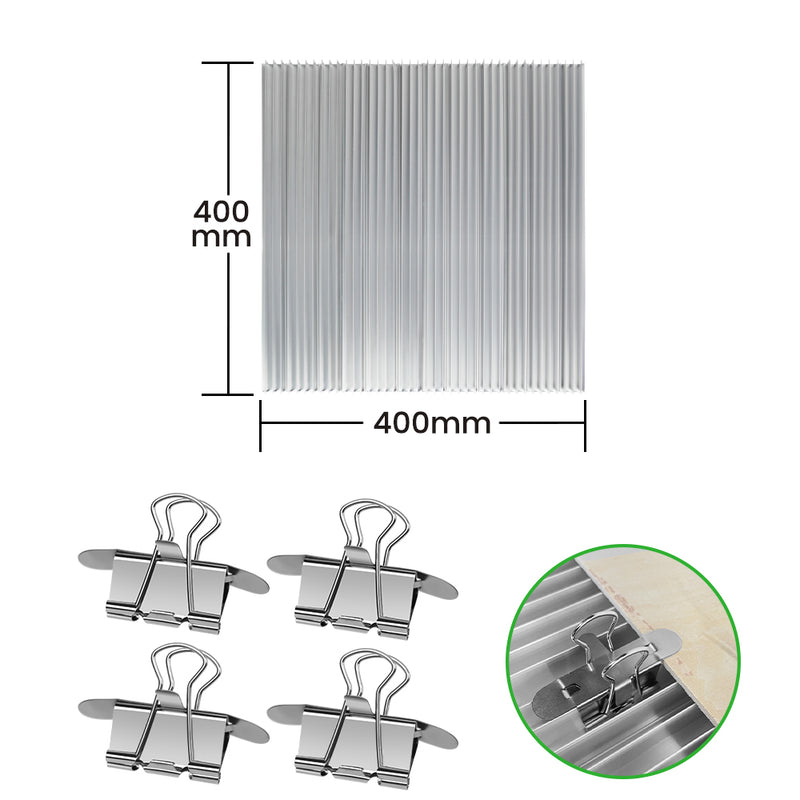

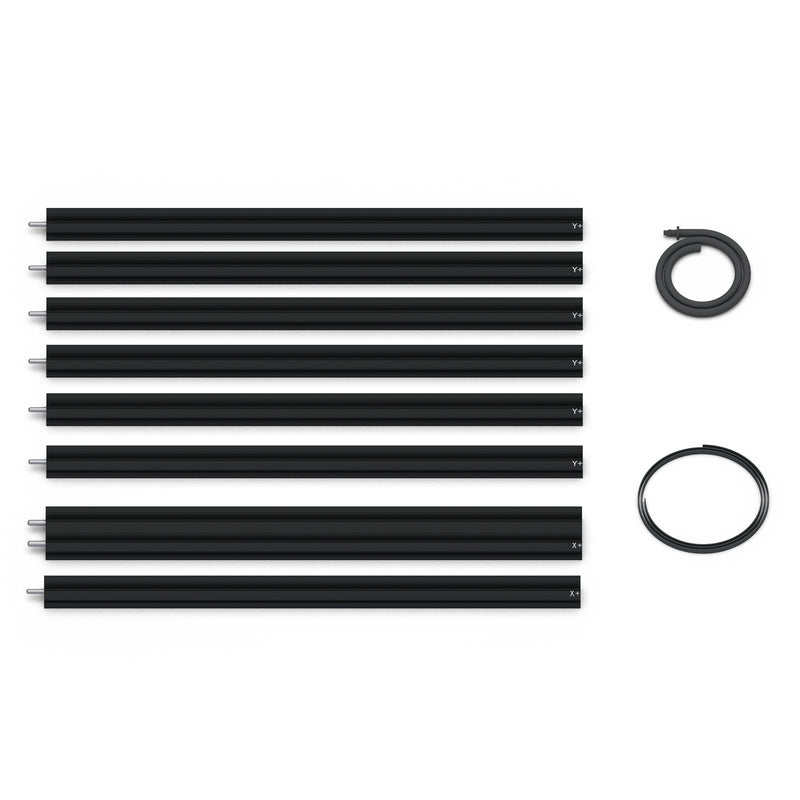

3.2 Super-Large, Extendable Work Area

Its standard 1250 × 2440 mm (4′1″ × 8′) bed can be expanded further via innovative Y-axis rail extensions, accommodating full-sheet materials without seams.

3.3 Fully Enclosed Safety & Exhaust

A sealed chamber with integrated automatic exhaust and multi-point safety interlocks prevents smoke or laser leakage, ensuring a clean and secure workspace.

3.4 Software Compatibility & Plug-and-Play

Pre-assembled and compatible with LightBurn, LaserGRBL, and TyvokStudio, S1 enables users to start engraving or cutting within minutes—no CNC expertise required.

4. Workflow: Precision Cutting Meets 3D Texturing

Design & File Export

Create vector contours (SVG/DXF) in LightBurn; prepare high-resolution PNG/JPEG color maps in eufyMake Studio.

Laser Cutting

Use Tyvok S1 to cut precise shapes on chosen substrate at optimized power and speed settings.

Auto-Alignment

Place cut piece on E1’s bed; its AI-driven dual-laser and SnapShot™ camera scan and align the contour, achieving “zero-error” registration.

3D-Texture UV Printing

E1’s Amass3D™ engine deposits successive UV ink layers to build up to 5 mm relief, while ColorMaestro™ renders ultra-vivid, true-to-life colors.

5. Real-World Applications

Custom Portrait Plaques

Laser-cut a silhouette in 6 mm cherry plywood with Tyvok S1; UV-print facial details and hair texture in relief for a gallery-quality hanging art piece.

Animal-Themed Decor

Vector-cut animal shapes on acrylic; use E1 to emboss fur patterns and gradient colors, creating eye-catching home décor or personalized pet gifts.

Small-Batch Product Prototyping

Combine S1’s large-format batch cutting with E1’s texturing for rapid prototyping of consumer electronics enclosures, custom signage, or limited-edition collectibles.

6. Who Should Buy Which?

DIY Enthusiasts & Makerspaces

Start with eufyMake E1 for intuitive, high-texture prints and expand into laser cutting later.

Design Studios & Small Businesses

Invest in Tyvok S1 and E1 together for an end-to-end solution: rapid vector cutting plus premium 3D-texture finishing.

Educational & Commercial Production

Deploy S1 for hands-on CNC instruction and bulk part cutting; use E1 for finishing, branding, and tactile prototyping.

Conclusion

By uniting eufyMake E1’s innovative 3D-texture UV printing with Tyvok S1’s large-format, high-power laser capabilities, creators unlock a seamless workflow from precise structure to vibrant texture. This synergy not only elevates the DIY desk setup but also scales to studio-level production—empowering you to literally print your imagination in three dimensions.