Our Story behind and Design Ideas

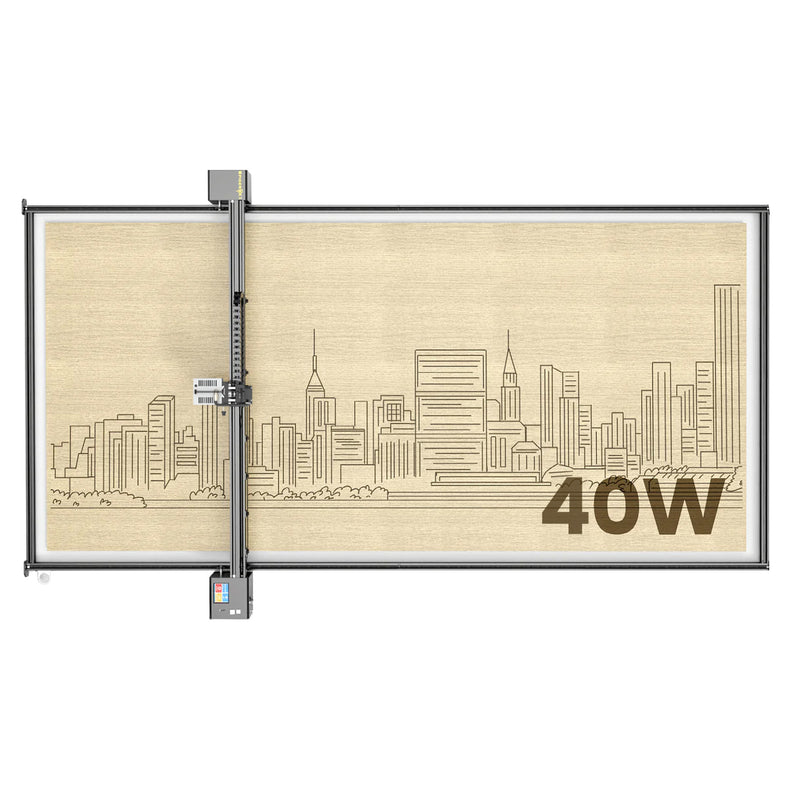

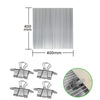

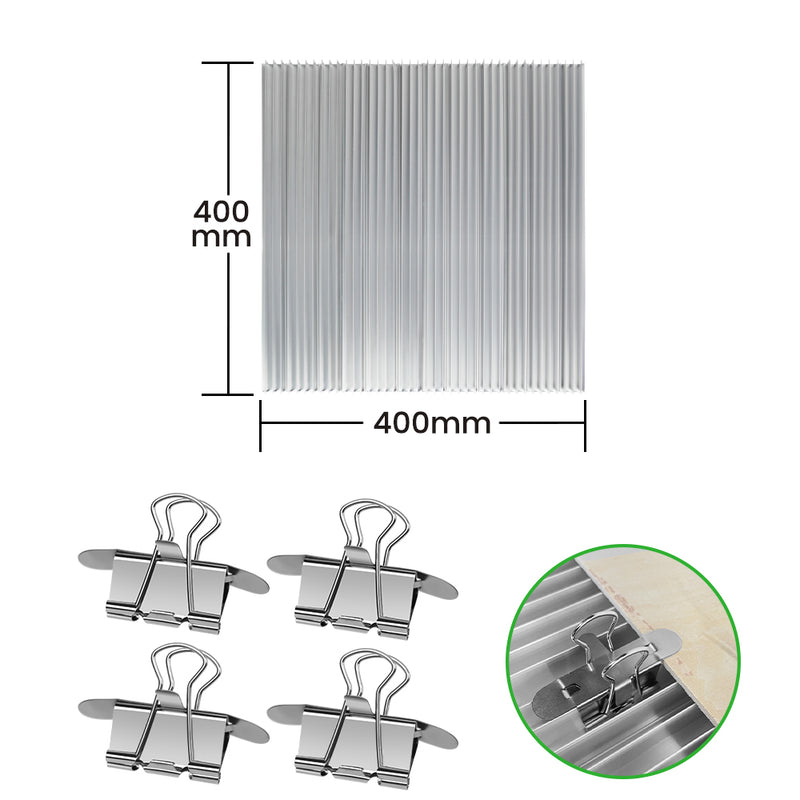

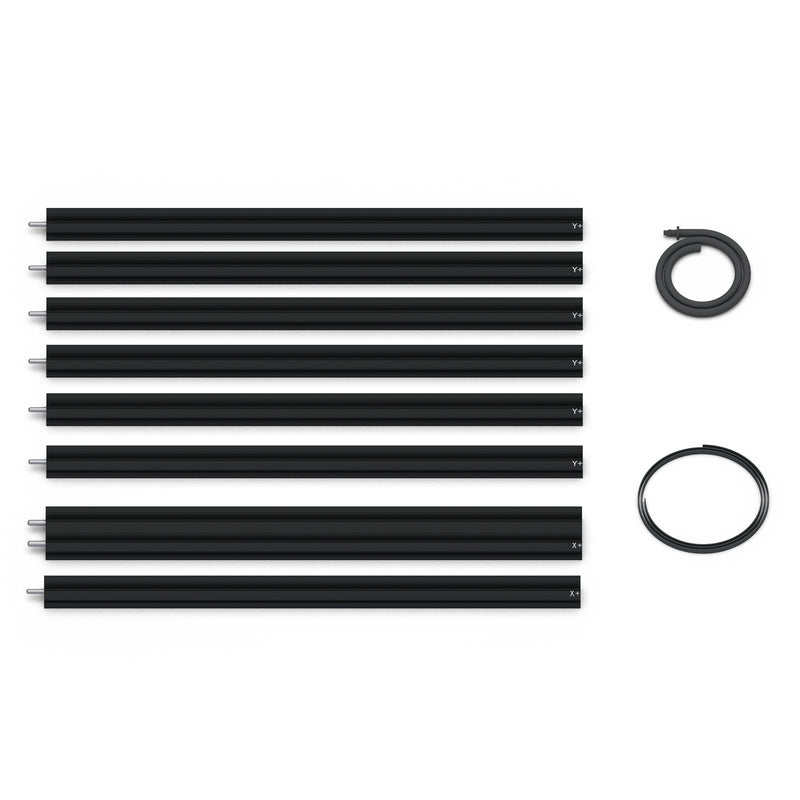

At present, there are many engraving scenes, and they are very subdivided, but the needs of users vary widely, and a single product cannot meet the needs of multiple scenes: How to make a product adapt to multiple scenarios and solve the main problems in the current laser engraving and cutting--Engraving should not be limited by physical space, to achieve full coverage of needs from small to large to wider, so we propose an infinite concept, hoping to have more inspiration for the development of engraving and cutting in the future However, in order to truly achieve infinity, we must get rid of the shackles of the current traditional design scheme. Improving the space through the frame structure will increase the volume, and the cost will continue to increase, and it is not portable. Therefore, we try to simplify to a highly integrated design, gradually optimize the frame structure to a cantilever structure, and finally simplify it to the Spider M1 single-arm structure. The Y-axis is adjusted from the traditional guide rail to the pulley structure, which gets rid of the limitation of the length of the guide rail and makes infinite possible But the problems that follow are also extremely difficult. How to make the Y-axis go straight? Through continuous experimentation and exploration, we have found solutions from automobiles and road rollers, and we have tried a variety of solutions. Finally, we focus on three schemes. After nearly a hundred experiments under the same conditions, the distance of 1000mm on the same plane of the same roller. Front drive: offset 1.31-1.52MM Rear drive: offset 1.53-1.86MM Four-wheel drive: offset 0.79-0.99MM In the end, the four-wheel drive solution performs better, but it is not enough. In order to further improve the progress of the Y-axis, through continuous experiments, we found that the width of the roller also plays a crucial role in the straightness of the Y-axis motion. Through long-term testing, the wider the roller, the better the motion straightness. After Spider M1 defines the X-axis engraving width as 200MM, the limit roller width reaches 400MM; In the case of four-wheel drive, the offset of 1000MM linear motion is 0.25MM, which basically reaches the machining accuracy, but the ultra-wide wheel will have higher requirements on the motion plane, which may causes the engraving accuracy to be very unstable. Therefore, the choice of material and friction for the roller belt will be very important.

1 comment on How To Make The Y-axis Go Straight?