CO₂ laser cutters are indispensable tools for makers, engineers, and businesses, but traditional models come with inherent design constraints. Focusing the laser typically involves moving a heavy workbed, and machine enclosures limit the size of materials that can be processed. The Tyvok K1 100W CO₂ laser cutter introduces a novel approach – integrating the laser tube with the moving head and using an open-frame, fixed-bed architecture – to overcome these challenges. Below, we explore how K1’s innovations in focusing mechanisms and platform design address the limitations of conventional CO₂ laser machines.

Limitations of Traditional CO₂ Laser Focus via Platform Adjustment

Most standard CO₂ laser cutters have a fixed-height laser head and rely on adjusting the work platform up or down to focus on the material’s surface. In a typical small laser (like the ubiquitous K40), the CO₂ tube is mounted separately at the back or side of the machine, and the beam is steered through multiple mirrors to the stationary cutting head. Because the head’s height is fixed, the only way to bring different material thicknesses into the laser’s focal point is by raising or lowering the bed (work platform). In practice, users often focus by moving the material to the laser’s known focal distance – for example, by turning knobs to adjust the platform height or even stacking spacers of a known height under the workpiece. This approach works for small machines, but it introduces several limitations as machine size grows:

-

Tedious Manual Focusing: Entry-level hobby lasers may lack motorized Z-axis movement, requiring users to manually adjust bed height (or shim the material with blocks) to fine-tune focus. This trial-and-error process can be cumbersome and error-prone, especially for beginners.

-

Platform Leveling Challenges: The workbed must remain perfectly level relative to the laser head’s travel plane to ensure uniform focus across the entire area. On larger machines, the bed is usually supported by screws at the four corners (often with manual or motorized leadscrews for leveling). Even a small tilt or sag – on the order of 1 mm – can cause the laser to defocus at one side of the working area, since the focal point might hit the material too high or low in that region. As bed size increases, maintaining a truly flat, rigid platform becomes increasingly difficult. Mechanical play, belt stretch, or slight bending in the supports can lead to one corner being lower than the others, magnifying focus errors over wide formats. The result is that on a large piece of material, some regions might cut cleanly while others are out of focus, failing to cut through or engraving weakly.

-

Heavy Moving Mass: The larger the bed, the heavier it is (especially with a honeycomb or blade table plus the material weight). Moving this mass up and down for focusing or during auto-bed leveling is slow and adds mechanical load. Over time, gravity can cause the platform or screw threads to wear or drift, requiring frequent re-calibration. Even if high-end machines add motors and sensors for “auto-focus” (e.g. a touch probe or ultrasonic sensor that moves the bed to the proper height automatically), the fundamental issue remains: the focusing mechanism is tied to a large moving platform that is hard to keep perfectly aligned and stable. Keeping a big bed flat over long-term use is a constant headache for engineers, as factors like screw backlash, frame flex, and weight distribution can introduce errors.

In summary, traditional CO₂ laser designs that focus via platform adjustment struggle with precision and consistency at larger scales. Even with assistive technologies, the user must diligently maintain bed levelness. This adds setup time and can reduce cutting quality for wide-format jobs. It became clear that a different focusing approach could greatly improve ease of use and accuracy.

Tyvok K1’s Integrated Focus and Smart Z-Axis Adjustment

Tyvok’s K1 laser cutter turns the conventional focusing scheme on its head – literally. Instead of fixing the laser tube to the chassis and moving the heavy workbed, the K1 integrates the laser tube directly into the gantry-mounted laser head assembly. The entire laser module (tube, mirrors, and focus lens) rides on the X-axis gantry, moving with the cutting head. To adjust focus, the K1 uses a motorized Z-axis in the head assembly that raises or lowers the laser head (along with the tube) relative to the fixed work platform. In other words, it brings the laser to the material, rather than bringing the material up to the laser. This integrated design was factory-calibrated for beam alignment, so users do not need to manually adjust multiple mirrors – the optical path is fixed and maintained out of the box.

Figure: Comparison of focusing mechanisms. Left: A traditional CO₂ laser cutter keeps the laser head fixed and moves the entire workbed up or down to focus, requiring the platform to be level. Right: Tyvok K1 integrates the CO₂ tube into the moving gantry and adjusts the laser head’s height for focusing, while the workbed stays fixed in place. This “moving head” auto-focus design eliminates heavy platform adjustments and keeps the beam consistently perpendicular.

This integrated focusing mechanism offers several key benefits. First, because the laser tube and optics move together as one unit, the beam alignment remains constant – the laser is always hitting the material at the correct angle and focal distance, even as the head moves up or down. There’s no risk of losing alignment due to moving a mirror or platform. Second, the mass being moved for focus is much smaller (just the lightweight gantry and laser module) compared to an entire table, which makes focusing adjustments faster and more precise. The K1’s head only needs to travel on the order of a few centimeters (its focus range is about 0–45 mm by default) to accommodate common material thicknesses, rather than the hundreds of millimeters of travel some lift tables have. This compact movement with tight control means the focal point can be set very accurately.

Crucially, the workbed on the K1 is fixed in place, rigidly mounted to the frame. Once it’s initially leveled during assembly, it doesn’t move during operation. This eliminates the recurring leveling/calibration tasks that plague traditional large-bed lasers. Because the bed is solid and stationary, the K1 can ensure the focal distance remains consistent across the entire working area – there’s no chance of one corner drifting out of plane and defocusing the beam. In short, the K1’s autofocus system “lets the laser head find the material” rather than forcing the user to jack up the material to find the focus. An integrated sensor measures the material height and the machine automatically drives the head to the correct focus position at the touch of a button, making focus setup essentially one-click and foolproof for the user. Even a beginner can get perfect focus across a large piece of material without manual shimming or trial-and-error. This smart Z-axis adjustment not only saves time but also greatly reduces human error in the focusing process.

The benefits of K1’s approach are evident in practice: There is no heavy platform moving up and down, so issues of inertia or wobble are gone. The machine is less mechanically complex in that respect, improving reliability. As noted in Tyvok’s documentation, the K1’s all-in-one laser head and auto-focus design streamlines operation and improves overall efficiency compared to traditional setups. By offloading the tedious focus and leveling tasks to an automated, integrated mechanism, users can achieve consistent results job after job. In essence, Tyvok K1’s integrated focus is reimagining how CO₂ lasers handle Z-axis adjustments, trading the “moving table” for a “moving laser head” to deliver precise, computer-controlled focusing with minimal user intervention.

Platform Design: Open vs. Enclosed Structure

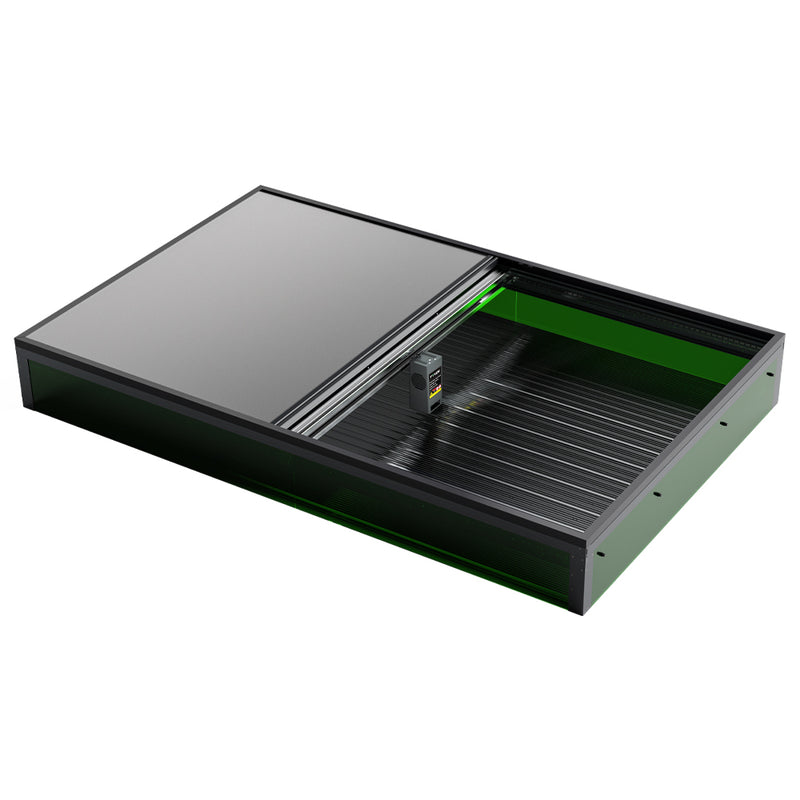

Another fundamental difference between traditional CO₂ lasers and the Tyvok K1 is the machine’s frame and platform design. Classic CO₂ laser cutters are usually built as closed or semi-closed boxes – a cabinet with four walls and a floor, with the laser bed inside. They often include small pass-through slots or doors on the front and back, allowing a limited-length piece of material to extend out if needed. For example, an 80 W hobby laser might have front/rear openings just a few inches tall, enabling some longer boards to slide through, but the overall workpiece size is still constrained by the inner dimensions of the enclosure. Moreover, even if the front door is open, the height of the material is limited by the distance between the adjustable bed (at its lowest position) and the machine’s top – you can only lower the bed so far before the floor of the machine stops you. In practice, standard machines might have Z-axis travel on the order of a few dozen to a couple hundred millimeters at most. You cannot load infinitely thick or tall objects; at some point the object simply won’t fit inside the box.

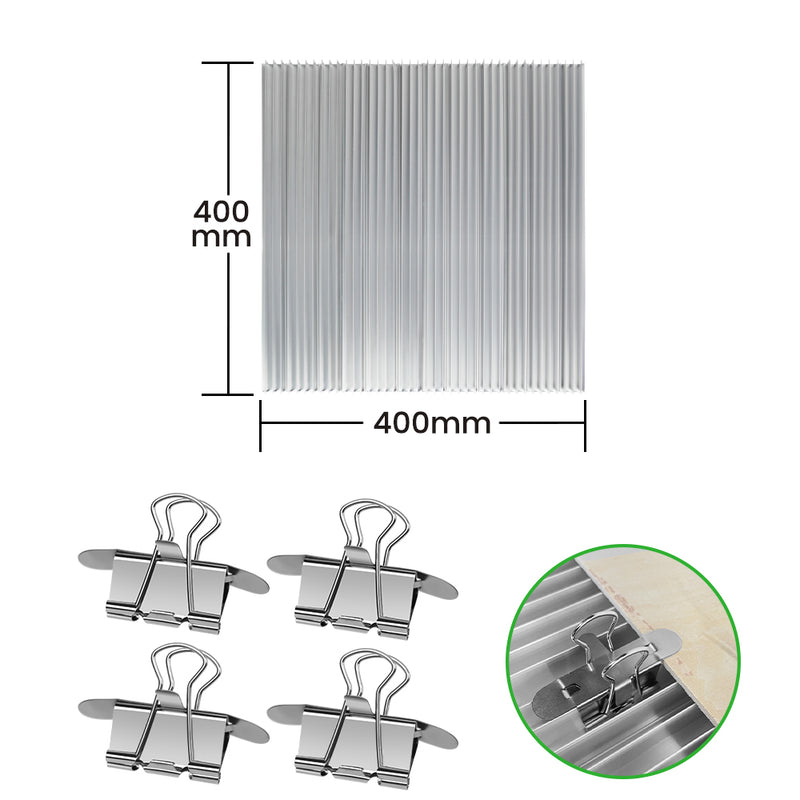

Tyvok K1 takes a very different approach with a semi-open, pass-through frame design. The K1 unit does have a top enclosure where the laser gantry and optics reside (including a transparent safety lid on the front for Class I operation during normal use), but the machine’s bottom is intentionally left open. The front and back of the machine are largely unobstructed as well (when the safety lid is opened or removed), creating a clear path through the machine from front to rear. In its standard configuration, the K1 can focus on materials up to about 45 mm thick placed on its fixed workbed, which covers typical sheet goods for engraving and cutting. But when users need to work with much thicker or taller objects, they can simply elevate the entire K1 or place it on a set of risers over the object. Because there is no fixed floor under the laser head, an oversized workpiece can protrude below the machine. In effect, you get a “bottomless” laser cutter for special projects. According to the manufacturer’s tests, the K1’s structure can directly accommodate objects up to 200 mm in height for engraving or cutting, and if the object is even taller, you can further raise the machine to suit the task. This is something practically unheard of in traditional enclosed laser systems. For example, one could engrave the back of a wooden chair or the side of an assembled piece of furniture by positioning the K1 over it – scenarios that a typical boxed laser simply could not handle.

Figure: Traditional CO₂ laser machines are closed-box enclosures (left), often with only a small pass-through slot, which limits the size and thickness of materials that can be processed. In contrast, the Tyvok K1’s open-bottom, open-frame design (right) allows long boards to be fed through front-to-back and lets tall objects extend below the machine for engraving. This open architecture vastly increases the range of workpiece sizes the laser can accommodate.

Because the K1 frame is open in the front and back, feeding very large or extra-long materials is straightforward. A board that is longer than the machine’s working area can be slid through from one end to the other, allowing for segmented processing of oversized designs without cutting the material into pieces. For instance, you could push a 2-meter-long panel through the K1, engraving or cutting a portion at a time, and then reposition it to work on the next section. There are effectively no hard length limits imposed by the machine’s enclosure. This capability is extremely practical for making large signs, furniture panels, or any project that doesn’t fit in a standard laser cutter’s bed. Some high-end traditional lasers do offer limited pass-through doors for this purpose, but those openings are typically still constrained and only useful for thin, flat materials. The K1’s wide-open frame, by contrast, has no significant barriers – loading bulky items or full-size boards is far more convenient. Likewise, the absence of a floor means that even very thick materials or 3D objects can be placed under the laser head. As long as you have the vertical clearance in your workspace to lift the K1 over the object, you can engrave things like the top of a guitar body, a large tree stump cross-section, or a tall trophy plaque – use cases that would stump a typical enclosed laser cutter.

It’s important to note that operating the K1 in this open-bottom or open-front configuration does mean losing the full protective enclosure. With the bottom removed or the pass-through in use, the machine’s laser safety rating effectively changes from a fully enclosed Class I system to an open Class IV laser device. This means the operator and bystanders will need to take additional safety precautions (such as wearing appropriate laser safety goggles and ensuring the area is controlled) whenever the laser is used in an open-frame mode. The K1 does maintain a top cover to block laser radiation from above and uses shielding where possible, but users should treat it like any other open-gantry laser cutter in these scenarios. For experienced engineers and DIY users, this trade-off is well worth it for the tremendous flexibility gained. Being able to work on large and unconventional pieces can unlock many creative and practical applications that would simply be impossible in a traditional closed-box laser. In summary, Tyvok K1’s platform design shifts from a fully enclosed, size-limited box to a semi-open architecture that safely balances access and protection. This open design reimagines what sizes and shapes of workpieces a desktop CO₂ laser can handle, greatly expanding the machine’s versatility.

K1’s Extended Advantages: Precision, Speed, Smart Features

Beyond its core focusing and frame innovations, the Tyvok K1 brings a host of performance and usability improvements that further set it apart from conventional CO₂ lasers. The design changes discussed above do not come at the expense of power or accuracy – in fact, the K1 matches or exceeds the capabilities of typical CO₂ machines on key specifications:

-

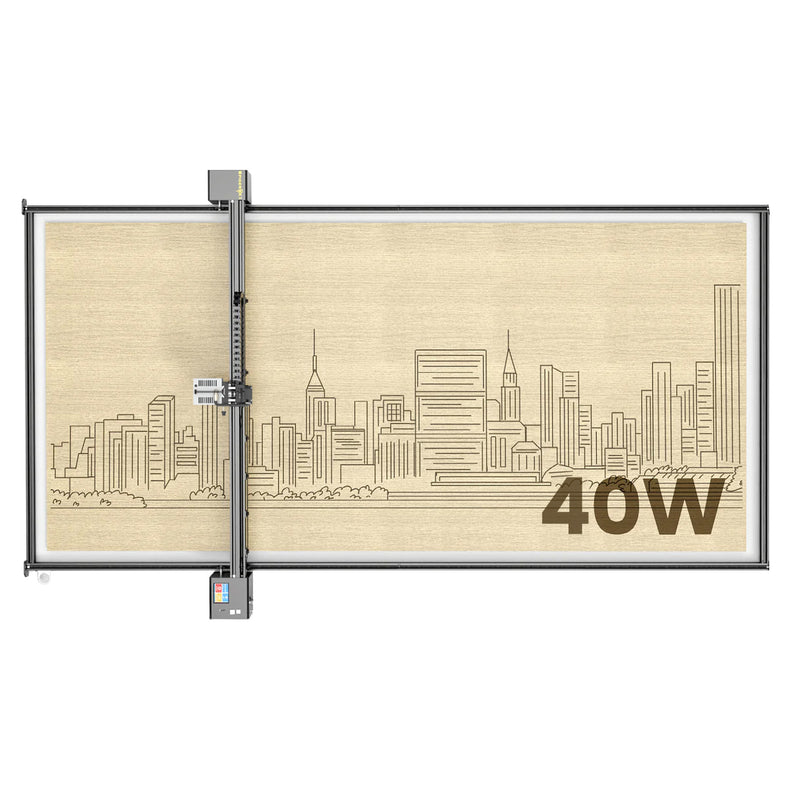

High Power and Cutting Capability: The K1 is equipped with a high-quality 100 W Yongli CO₂ laser tube, known for a stable beam mode and reliable output. This gives it plenty of cutting power – for example, it can cut through 20 mm thick wood in a single pass under the right settings. Such cutting performance is on par with many larger industrial machines. The tube’s integration in the moving head does not compromise its effectiveness; instead, it ensures the beam delivery is short and direct. Combined with K1’s air-assist and optics, users can achieve clean cuts with minimal burn marks on thick materials, leveraging the full 100 W without the losses that sometimes occur in long mirror chains.

-

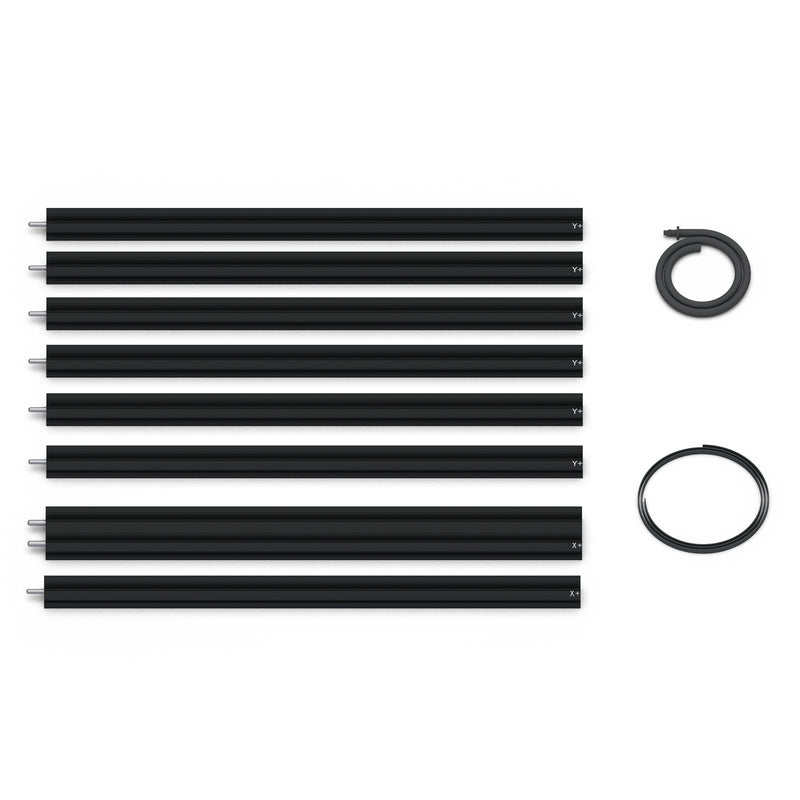

Precision and Mechanical Stability: The Tyvok K1 uses precision linear guides and a dual Y-axis leadscrew drive system to move the gantry. This rigid mechanical setup yields a repeatable positioning accuracy of about ±0.05 mm across the entire working area. In practical terms, that means if you cut interlocking parts or intricate patterns distributed around the bed, they will align and fit together cleanly without cumulative error. The fixed-bed, moving-head architecture contributes to this precision – since the workpiece isn’t being jostled up and down for focusing, one major source of error is eliminated. Users can trust the K1 for finely detailed engraving and tight tolerance cuts (for example, puzzle pieces or press-fit assemblies) just as well as for brute-force cutting of thick stock.

-

High Speed Motion: Laser jobs that involve a lot of engraving (raster scanning) or long travel moves benefit greatly from higher motion speed. The K1 is capable of very rapid movement – with maximum engraving or travel speeds up to 1000 mm/s (around 1 m/s). This is significantly faster than many hobby-class CO₂ lasers, which might top out at a few hundred mm/s. The K1’s ability to achieve such speed is thanks to its lightweight moving head (since the design removed extra weight like long drag chains or heavy laser tubes on the frame) and the use of high-torque servomotors. The machine can accelerate quickly and maintain stable motion without excessive vibration or overshoot. Even at high speeds, the cut or engraving quality remains high – fine details are not lost to shaking or “wobble” lines. For users, this means improved productivity: large engraving projects or batch jobs can be completed much faster, without sacrificing precision or risking skipped steps. In a production or workshop setting, this speed advantage can translate to higher throughput and better efficiency.

-

Smart Features and User-Friendly Operation: Tyvok K1 is designed to be compatible with the workflows that users already know. It supports industry-standard laser control software like RDWorks and the popular LightBurn software, as well as Tyvok’s own simple control software. This flexibility means both advanced users and newcomers can use the interface they prefer. Moreover, the K1 comes with a built-in high-definition camera aligned to the work area. Through the software, you can view a live image of the bed and drag-and-drop your design exactly where you want it on the material (a “what you see is what you get” placement). This camera-assisted positioning eliminates the guesswork of manually jogging the laser to a start point or using tape measurements to align a job – it greatly speeds up setup for engraving existing objects or odd-shaped pieces. The autofocus we discussed earlier ties into this as well, allowing you to simply place a new material in the machine, close the lid, and start the job with confidence that the focus is correct and the artwork is aligned. The K1 also features modern connectivity like Wi-Fi, so you can send jobs to the laser wirelessly or monitor its status remotely, akin to a contemporary consumer printer. All these touches make the K1 feel much more “plug and play” compared to older lasers that might require tinkering and manual adjustment for each job.

-

Efficient Fume Extraction and Cooling: Laser cutting and engraving produce smoke, vaporized material, and fumes that need to be removed to keep the optics clean and maintain a safe environment. The K1 addresses this with a dual-channel exhaust system that automatically switches modes depending on cutting or engraving operations. For example, it may use a high-flow mode when cutting (to pull out the thicker smoke from burning through material) and a quieter, fine suction mode when engraving (to gently remove smoke without disturbing light materials). The machine’s enclosure and an under-bed exhaust port work together to capture fumes both from above and below the workpiece. This coordinated airflow keeps the laser lens and mirrors cleaner (since smoke is sucked away before depositing on them) and also helps minimize odor and haze in the room. Tyvok emphasizes that the K1’s exhaust design, combined with the enclosure, makes it suitable for use in offices, labs, or classrooms where maintaining air quality is important. In essence, the K1 strives to contain the mess and smell that CO₂ lasers can generate, resulting in a more pleasant and maintenance-free experience. (Additionally, the machine integrates a water-cooling system for the laser tube in a compact form, ensuring stable laser output without the need for a separate chiller unit, though this is more of a standard feature for a laser of this class.)

All of these extended features illustrate that the Tyvok K1 is not just a one-trick pony focusing on automation – it is a well-rounded, high-performance laser cutter. The precision, speed, and smart features mean that users aren’t trading off quality or capability to get the convenience of the new focus/platform design. On the contrary, the K1 aims to deliver industrial-grade results (high power, fine accuracy) in a package that is also user-friendly and adaptable. It represents a modern generation of CO₂ lasers that blend professional performance with maker-oriented flexibility.

Real-World Use Cases: Thick Material Engraving, Cylindrical Objects, Long Panel Cutting

To truly appreciate how Tyvok K1’s focus and platform innovations translate into real-world advantages, let’s consider a few scenarios that are challenging for traditional CO₂ lasers but become much easier with K1’s design:

-

Thick Material Deep Engraving: Imagine a DIY maker who wants to engrave a detailed relief pattern into a solid wood plank 50 mm thick for a custom piece of furniture. On a conventional CO₂ laser, this project would be extremely challenging. First, you’d need a machine with enough Z-axis clearance to even fit a 50 mm thick board (many hobby lasers might not accommodate that height). Even if the board fits, standard focus lenses have a limited depth of field – the optimal focus is only a few millimeters deep, near the surface of the material. Engraving deeper into the wood would quickly fall out of focus. The traditional workaround would involve lowering the bed and refocusing for each deeper layer, if possible, or using lenses with longer focal lengths (with trade-offs in spot size and power density). By contrast, using the Tyvok K1, this same maker can simply open or remove the K1’s bottom panel and place the thick wood board on the floor or a low stand, with the K1 chassis positioned over it. The K1’s laser head can autofocus on the board’s surface and begin engraving the top layer of the design. If a deeper engrave is required, the user can periodically pause to remove the charred layer or adjust the design, and the K1 will automatically refocus itself for each pass as the engraving goes deeper. The fixed, stable platform ensures that each successive layer of the relief is etched at the correct focal distance, maintaining uniform engraving depth and detail. The entire process requires no machine modifications or tricky re-leveling – something that would have been nearly impossible on a standard laser is made feasible by the K1’s open-frame and moving-head system. In short, K1 enables deep engraving on thick materials with ease, unlocking creative possibilities (like 3D wood carvings and thick inlays) that users would normally shy away from.

-

Cylindrical Object Engraving: Consider a small business that wants to etch logos and designs onto cylindrical objects like custom wine bottles, tumblers, or thermos flasks. Traditionally, this requires a rotary attachment that fits inside the laser machine. The cylinder is laid down in the machine and rotated while the laser engraves around its surface. However, many enclosed lasers have limited vertical space – a large-diameter wine bottle or an especially tall thermos simply might not fit inside the box with the rotary device, especially once you account for focusing distance. Even if it fits, aligning the laser focus on a curved surface can be tricky. With Tyvok K1, there’s a much simpler option: the user can set up a rotary roller or chuck outside the K1, and then place the entire K1 unit over it. Because there’s no bottom in the way, even a tall bottle can stand upright (or a long tube can be placed) under the laser head. The K1’s head is then lowered to the appropriate focus height on the surface of the bottle and the job is started. The bottle will rotate on the external roller as the K1’s head moves along the X-axis, effectively wrapping the engraving around the circumference. From the operator’s perspective, this workflow is almost as straightforward as flat engraving – there’s no need to cram the object into a tight machine space or jerry-rig the focus. The open design removes size barriers; even if the object is, say, a large wooden barrel or a ceramic vase, as long as the K1 can straddle it, you can engrave it. This capability allows small businesses or makers to expand into products like personalized drinkware, decorative pipes, or engraved drums, without investing in a much larger machine. The platform’s openness gives them the freedom to take on custom cylindrical jobs that used to be impractical. And importantly, they can do so with the same ease as a normal flat engraving, since K1 handles the focus and the mechanics don’t fight the object’s size. The result is a smooth engraving around round objects, enabled by the K1’s unique form factor.

-

Extra-Long Panel Cutting: Now imagine a workshop needs to cut a continuous pattern (say, a decorative lattice or a series of slots) along the length of a 2 m long wooden board for an interior design project. A traditional approach might require either using a very large-format laser cutter (which is expensive and takes up huge floor space) or attempting to cut the pattern in sections on a smaller laser and then manually splicing the pieces together. The Tyvok K1, especially the larger Max variant with a 1200 × 2000 mm working area, is already capable of handling near-full-sheet dimensions in one go. But even if the board exceeds its bed, the K1’s pass-through design can handle it. The workshop could start by feeding one end of the long board into the front of the K1 and aligning the design to that section. The laser cuts the first portion of the pattern on the board. Then, using a simple jig or registration marks, the board is slid through to present the next section of the pattern under the laser, and the K1 continues the cut, and so on down the length of the board. Thanks to the fixed platform and automatic refocusing, each time the board is repositioned, the laser re-focuses correctly on the surface and the bed remains level, so the cut pattern segments line up perfectly with each other. There’s no misalignment at the seams due to bed tilt or focus error, which can be a problem if you try to do this in a machine where the bed might not return to the exact same height each time. In the end, the entire 2 m board is cut with a continuous design that looks like it was done on a single enormous machine – but it was achieved with a desktop-sized K1 using a step-and-repeat method. This scenario highlights how K1 turns what could be a logistical challenge into a manageable task. It brings a production technique (continuous pass-through cutting) into reach for small workshops, without needing an expensive specialized laser. The ability to feed material incrementally through the machine effectively gives the K1 a “virtual” working area much larger than its physical bed. For creators making large signage, long architectural pieces, or oversized stencils, this capability can be a game-changer in terms of efficiency and cost. K1 handles it with aplomb, whereas a traditional enclosed laser of the same price class simply couldn’t tackle a job of that length or would require very cumbersome workarounds.

These use cases demonstrate the creative freedom and practical flexibility that Tyvok K1’s design provides. Tasks that used to be impractical or time-consuming on a CO₂ laser become straightforward. Whether it’s working with very thick materials, oddly shaped objects, or extra-large dimensions, the combination of a fixed, open platform and movable auto-focusing head lets the user adapt the machine to the project, rather than being forced to adapt the project to the limitations of the machine. For makers and businesses alike, this opens up new possibilities – from engraving assembled objects or furniture, to taking custom orders that previously would have been turned down due to size constraints.

Conclusion: How Tyvok K1 Reimagines CO₂ Laser Cutting

By integrating the laser tube with the motion system and adopting an open-frame fixed-bed design, Tyvok K1 effectively solves the two major pain points of traditional CO₂ laser cutters: focusing and platform leveling. For engineering teams and fabrication labs, K1’s design means far less time spent on fiddly alignment and calibration, and more time with the machine productively cutting or engraving. The focusing process is largely automated and foolproof, improving consistency across jobs and reducing downtime for adjustments. For business owners considering an equipment investment, the K1 offers a kind of future-proof versatility – its modular, expandable platform means one machine can handle a wide variety of tasks and material sizes, and even allows for potential upgrades (for example, Tyvok has hinted at power upgrades or extension kits) without needing an entirely new laser. This flexibility protects the investment and extends the machine’s useful life as needs grow. And for hobbyists and DIY creators, the K1 significantly lowers the barrier to entry for advanced laser work. Automatic focusing and smart vision alignment make features that were once considered expert-level (like perfect focus or precision registration) accessible at the push of a button, while the open structure gives them freedom to experiment with oversized or unconventional projects. All of this is achieved without sacrificing performance – the K1 delivers high power, fine precision, fast speeds, and a suite of safety and convenience features (like effective fume extraction and cooling) that collectively make it a state-of-the-art laser cutter for 2025

In essence, Tyvok K1 presents a new design philosophy for CO₂ lasers: use a lightweight moving laser module in place of a heavy moving workbed, and use an open, adaptable frame instead of a rigid closed box. These two shifts bring a double benefit of enhanced productivity and creativity for the user. Engineers get a machine that stays in tune and cuts reliably across its full area. Business users get more throughput and capability out of a single unit (with features on par with industrial systems), and creative makers are no longer limited by the physical confines of a small box. It’s a reminder that laser cutter design doesn’t have to remain static – even a technology as established as the CO₂ laser can be improved substantially with clever re-engineering. One early user of the K1 described their experience by saying, “K1 makes large CO₂ laser projects feel as easy as using a desktop machine.” This sentiment sums up the impact of Tyvok K1’s innovations: it brings the ease-of-use and agility of a desktop device into the realm of large-format, powerful laser cutting. That is high praise indeed, and it signals an exciting development in the laser cutting field – one where traditional limitations are being lifted, and users are empowered to take on bigger, bolder ideas with confidence and ease.

Ultimately, Tyvok K1 reimagines CO₂ laser cutting by addressing old frustrations with a fresh design. It shows that with thoughtful innovation in focus mechanisms and platform architecture, a laser cutter can achieve new levels of convenience and capability. Whether you’re an accuracy-obsessed engineer, a cost-conscious entrepreneur, or a boundary-pushing DIY creator, the K1’s approach offers something truly valuable: a laser cutter that adapts to your needs, rather than forcing you to work around its constraints. It’s a leap forward that brings new energy to CO₂ laser technology and opens up endless possibilities for what users can create.