We sat down with Mr. Sun, CTO of Ruida—one of leading laser control system companies—to talk about where CO₂ laser technology is heading and how those insights shaped the Tyvok K1.

From Factory Floors to Classrooms and Studios

“CO₂ used to be almost entirely industrial,” Mr. Sun noted. “Now we’re seeing schools, small studios, and individual makers adopt it.” What’s changed isn’t just component cost—it’s expectations. Users no longer want a giant box that demands a technician. They want tools that are safer, smaller, and easier to learn, with workflows that feel familiar.

That shift—away from raw specs and toward approachability—is the backdrop for K1.

Making CO₂ Feel Approachable

The first impression of K1 is its compact, modern look. “It’s a clear departure from the heavy, closed cabinets most people associate with CO₂,” Mr. Sun said.

Approachability goes beyond looks. In internal comparisons using the same engraving area, K1’s outer frame aims for ~90% usable frame efficiency versus ~50% in some conventional layouts (internal estimate). The result is a machine that fits into more places and invites users to get close, observe, and learn.

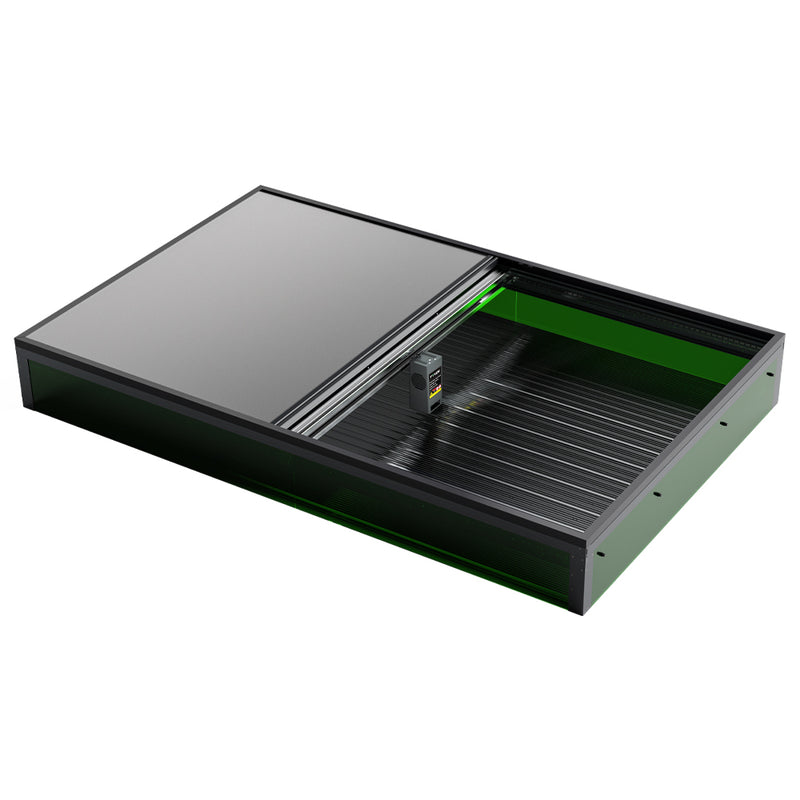

Semi-Enclosed, With Airflow That Adapts to the Job

Most CO₂ systems are fully enclosed for safety and fume control. K1 takes a different path: a semi-enclosed chamber paired with dual-direction exhaust that switches between top and bottom extraction depending on the job. The goal is to keep fume removal effective without slowing down material loading and iteration.

Safety remains non-negotiable: lid-triggered power cut-off, interlocks, e-stop, fuse protection, grounding, and room to mount a mini fire extinguisher. “If airflow management is well-tuned, this approach is especially helpful for classrooms and teams that open the lid often,” Mr. Sun observed.

Auto Focus and a Top Camera: Reducing Guesswork

“Is that auto focus? I usually see this only on larger industrial systems,” Mr. Sun asked.

K1 integrates a compact auto-focus module that measures the distance to the work surface and automatically sets the focus. For new users, that means fewer retries and more predictable results across materials of different thicknesses. A top-mounted wide-angle camera provides real-time preview and one-click alignment inside Tyvok Studio—something widely requested in maker communities.

Together, these features turn setup from a technical chore into a straightforward step.

Motion System: Fast Without the Wobble

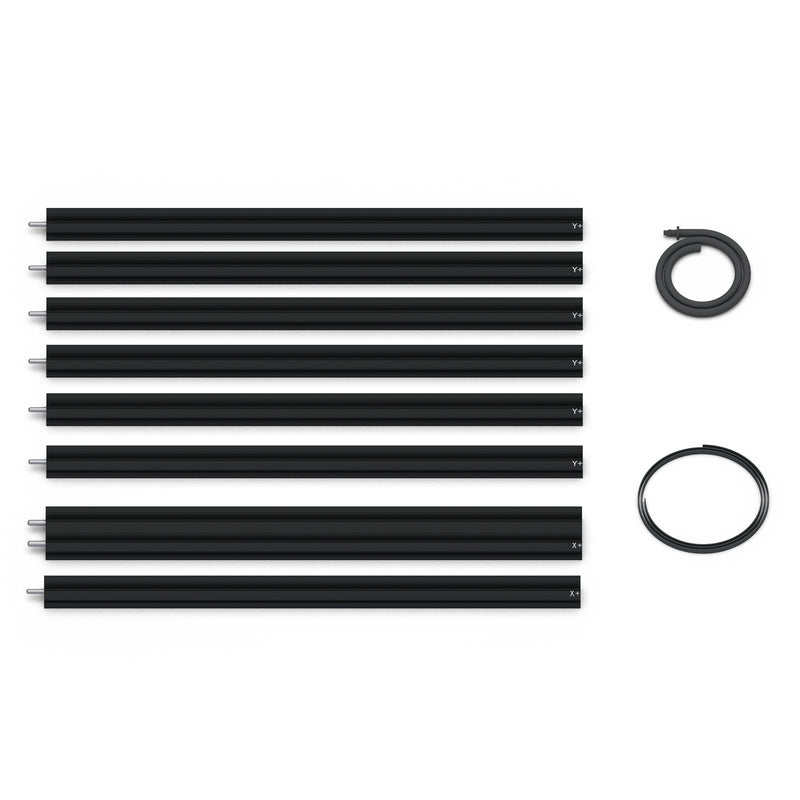

When we pushed the gantry, Mr. Sun immediately looked at the Y-axis. “Dual lead screws?” he asked. Yes—one per side, synchronized by belt. Combined with a high-performance motion stack, K1 reaches up to 1000 mm/s on the X-axis while keeping corners clean and curves smooth.

“Speed is only useful if the path stays true,” Mr. Sun said. “This is solid for its class.”

Software and Connectivity: Start Simple, Scale Familiar

K1 ships with Tyvok Studio, a free, graphical application designed to shorten the first week of learning. It also supports Wi-Fi file transfer to eliminate cable shuffling. Just as important, K1 is compatible with LightBurn, so experienced diode users can keep their habits and libraries intact. Unbox, connect, and get to work—no detours.

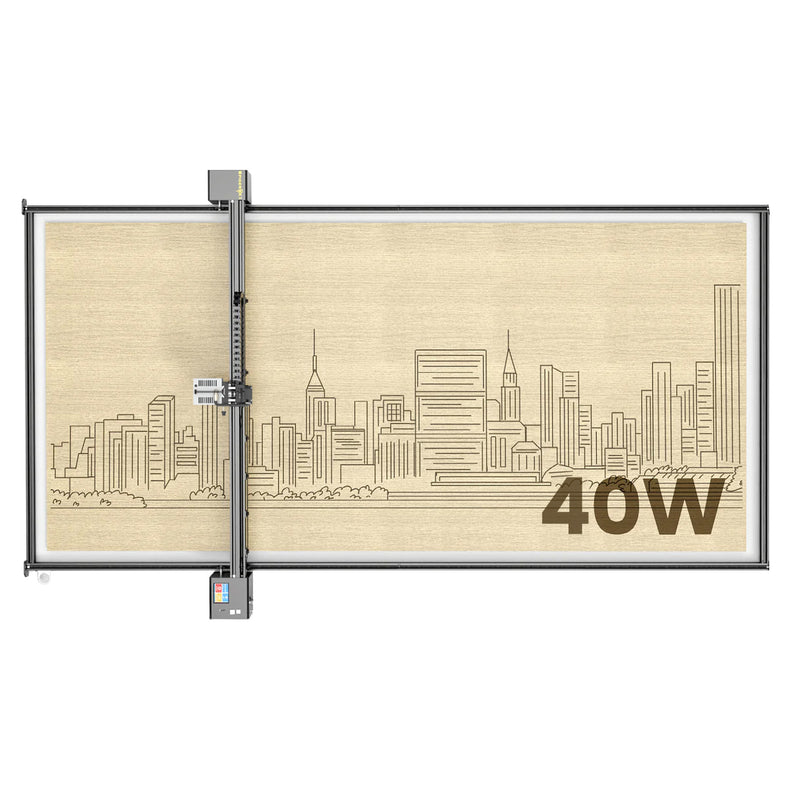

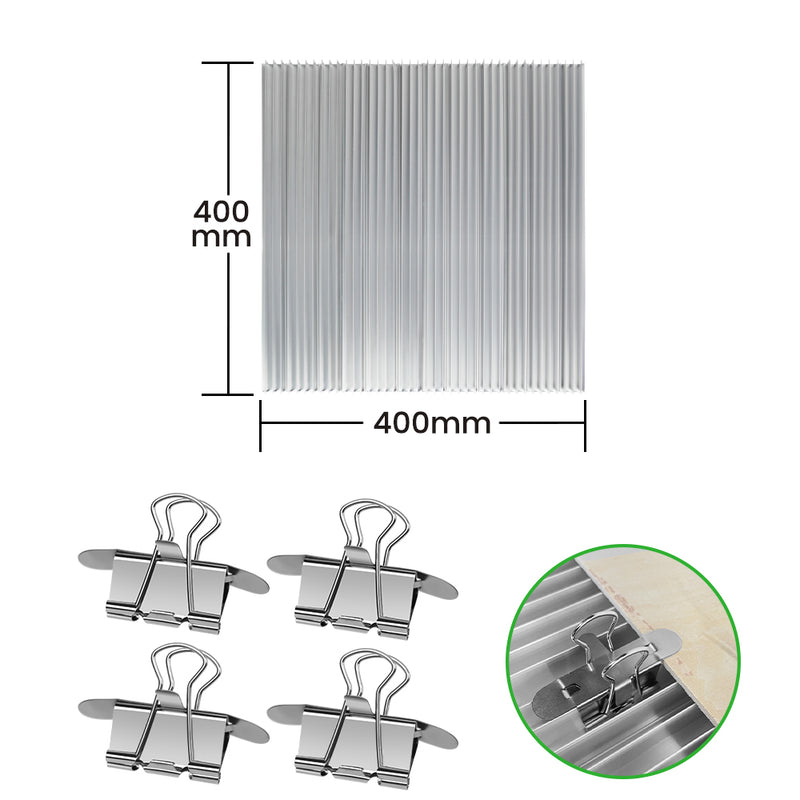

Full-Sheet Handling and a Clear Model Roadmap

K1 Standard offers a 1200 × 700 mm working area—enough for a full 4×2 ft (1220 × 610 mm) board, often without pre-cutting. The lineup is designed to scale with teams:

-

800 × 400 mm — compact for hobbyists and startups

-

1200 × 700 mm — our standard flagship (full 4×2 ft)

-

1200 × 2000 mm (planned) — for light industrial and batch production

“Consistent features across sizes make upgrading a lot less painful,” Mr. Sun said.

Materials That Unlock Creativity

Transparent acrylic and glass are classic examples where CO₂ shines and diodes struggle. On K1, acrylic edges came off polished with no whitening; glass engravings were clean and crack-free. “For custom gifts and education, that material flexibility matters,” Mr. Sun added.

Tube, Support, and the First-Run Experience

K1 uses Yongli CO₂ tubes, known for stability and broad service coverage. Each machine is pre-assembled and calibrated, so first-time users can start making without a full day of setup.

“You didn’t just chase numbers,” Mr. Sun said as we wrapped. “You focused on real user pain points—accessibility, setup, handling—without forgetting performance.”

Before he left, we engraved a small commemorative plaque (Tyvok × Ruida ) on K1 to mark the visit. “I’ll proudly put this in my office,” he smiled.

What We’re Aiming For

K1 is our answer to a simple question: How do we keep the power of CO₂ while making it feel friendly to diode users, educators, and small teams?

Our approach is to keep what works—familiar workflows, dependable motion, real safety—and rethink what gets in the way: size, opacity, and setup friction. Where you go from there—bigger formats, higher power—is a matter of growth, not a leap of faith.

Notes: Frame utilization and some values above are internal estimates; final specifications follow the production model.