For professional woodworkers, a laser cutter/engraver isn’t just a tool—it’s a partner in transforming raw wood into masterpieces. Whether you’re crafting intricate furniture inlays, producing commercial signage, or pushing the boundaries of wood art, the right machine must balance precision, power, and adaptability. This guide cuts through the noise to highlight the top 4 wood laser cutters & engravers for 2025, backed by technical expertise and real-world performance data.

1. Tyvok S1 (1250x2440mm Ultra-Large Bed, 60W Diode Laser) – The Industrial-Scale Innovator

Best For: Large-scale furniture manufacturing (table tops, wardrobe panels), architectural installations.

Why It Stands Out:

Why It Stands Out:

- Full-Sheet Cutting: Handles 1220x2440mm (4x8ft) sheets in one pass, eliminating alignment errors for furniture prototypes and architectural models .

- Adaptive Power Technology: 60W diode laser with adjustable power (20–60W) optimizes for wood density—60W for thick hardwoods, 20W for softwoods.

- AI Defect Avoidance (Optional): 12MP camera maps knots and cracks, rerouting paths to boost material yield from 75% to 85–90%.

- Performance: Cuts 30mm walnut at 60W power and 8 mm/s, achieving industry-leading vertical edge precision (≤0.05mm).

Key Insight: Diode lasers are gaining traction in industrial woodworking due to their energy efficiency and ability to cut thick materials without CO₂ tube replacements. The Tyvok S1’s AI vision system reduces waste, a game-changer for high-volume workshops .

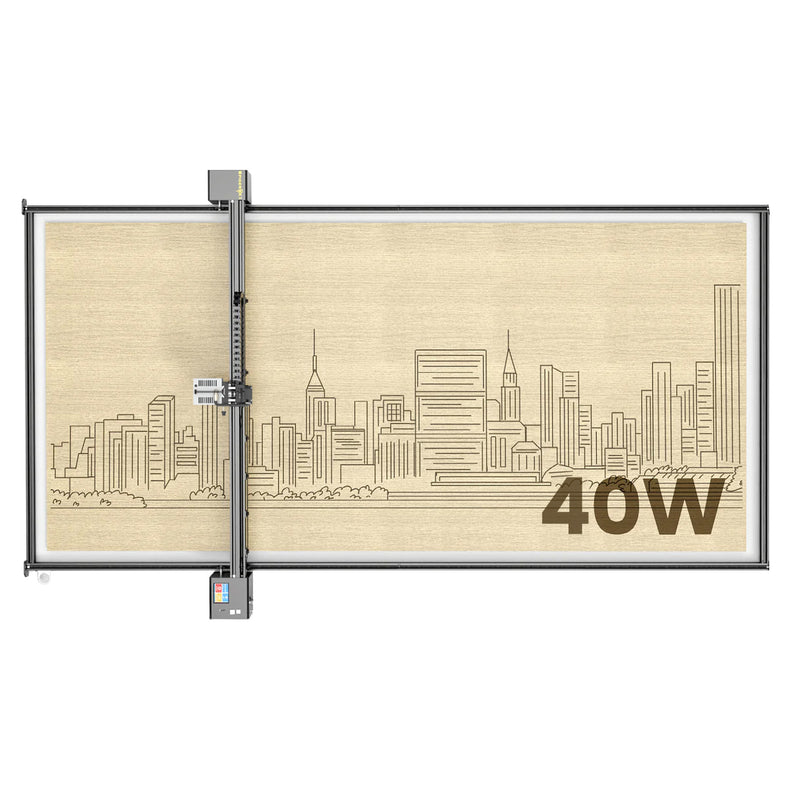

2. Brand S1 (40W Diode Laser) – The Detail Master

Best For: Fine engraving, jewelry boxes, custom signage, and woodblock art.

Why It Stands Out:

Why It Stands Out:

- 0.06mm Micro Spot: Captures hairline details (0.1mm lines) with zero jagged edges, ideal for replicating traditional woodcut artistry .

- AI-Powered Tracing: Converts photos to vector paths in seconds, supporting 600dpi precision for intricate patterns.

- Fume-Free Design: Built-in filtration eliminates the need for external ventilation—critical for workshops in confined spaces.

- Performance: Engraves 3mm birch at 40% power and 200 mm/s, achieving 120 lines per inch for gallery-worthy finishes.

Key Insight: Diode lasers like the Brand S1 excel at engraving delicate materials (e.g., basswood, veneers) without scorching. Their smaller spot size outperforms CO₂ lasers for micro-detailing, making them indispensable for artisans and small-scale creators .

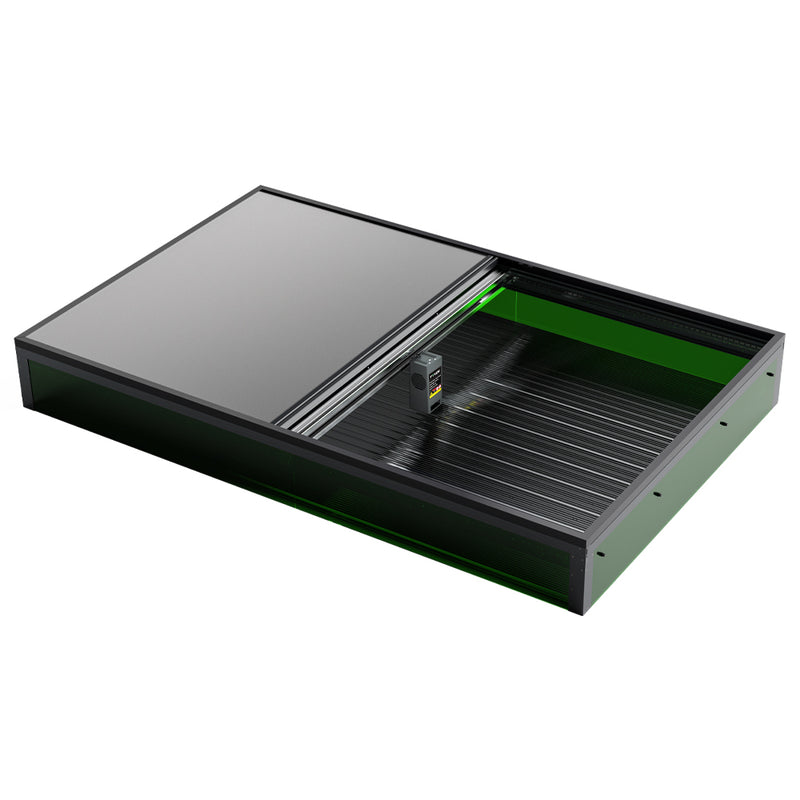

3. Brand Cloud 50W (CO₂ Laser, 600x900mm Bed) – The Mid-Range Workhorse

Best For: Small-to-medium batch production (wooden boxes, moldings, furniture parts).

Why It Stands Out:

Why It Stands Out:

- Dual-Temp Cooling: Extends laser tube life to 10,000 hours—3x longer than most models—perfect for daily use.

- Smart Remote Control: Adjust settings via smartphone, monitor progress in real time, and manage multiple machines remotely.

- Budget-Friendly Power: Delivers 50W CO₂ performance at 40% less than comparable imported models, ideal for startups.

- Performance: Cuts 12mm pine at 65% power and 28 mm/s, producing 10 furniture panels per hour with minimal post-processing.

Key Insight: CO₂ lasers dominate mid-range production due to their ability to cut thick hardwoods (up to 25mm oak) in single passes. The Brand Cloud 50W’s adaptive airflow system reduces charring by 40% compared to standard setups .

4. Brand Laser Master 3 (20W Diode Laser, Expandable Bed) – The Versatile Innovator

Best For: DIY creators, sample making, educational workshops.

Why It Stands Out:

Why It Stands Out:

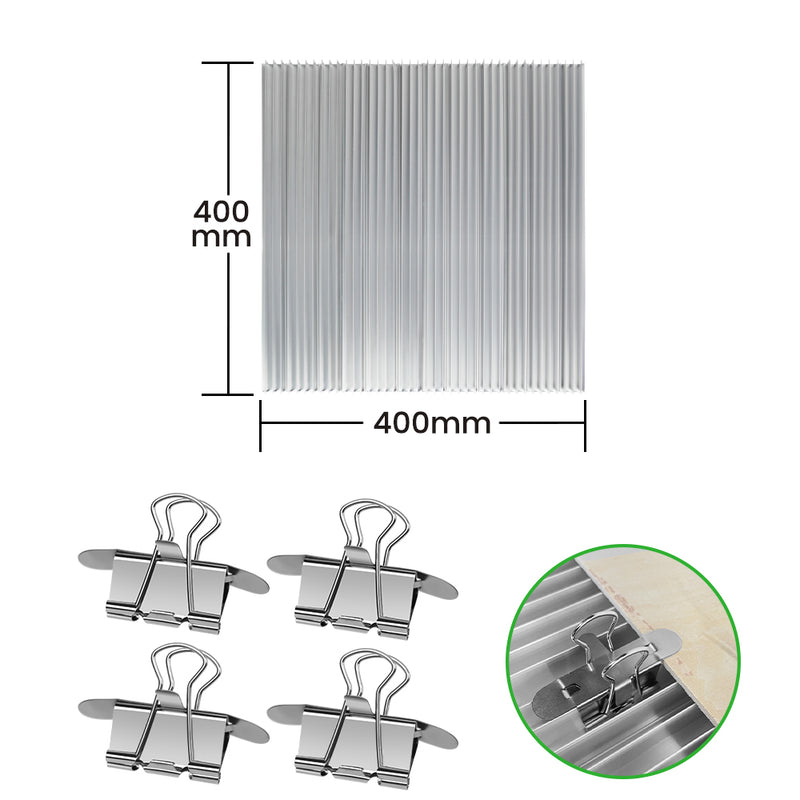

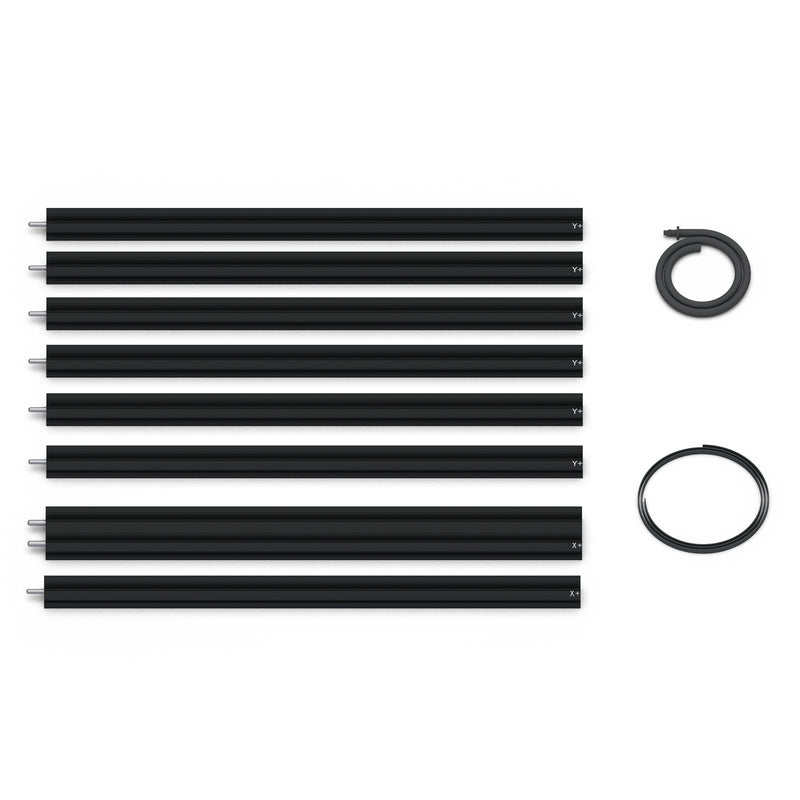

- Modular Design: Expand the working area to 930x430mm with add-on kits, balancing detailed miniatures and medium-sized projects.

- Dual Cooling System: Combines air and water cooling for 4+ hours of continuous use without power drop-off.

- LightBurn Ready: Unlocks advanced features like 3D relief carving and dynamic focus, reducing learning curves for beginners.

- Performance: Engraves 5mm basswood at 50% power and 300 mm/s, delivering 0.01mm positional accuracy.

Key Insight: Budget-friendly diode lasers like the Ortur Laser Master 3 are ideal for prototyping and small-batch crafts. Their portability and software compatibility (e.g., LightBurn) make them popular in educational settings .

Critical Considerations for Professional Woodworkers

1. Material & Laser Type

- Hardwoods (Oak, Walnut): Require 60W+ CO₂ or 20W+ diode lasers with high-pressure air assist (4 bar) to minimize scorching .

- Softwoods (Pine, Basswood): Thrive with 40W CO₂ or 10W diodes, using 30–50% power and speeds up to 400 mm/s.

-

Grain Direction:

- With the grain: Slow down by 20% and increase airflow to avoid fiber fraying.

- Against the grain: Boost power by 10–15% and use ≤0.08mm spot sizes for splinter-free edges.

2. Industry Trends Shaping 2025

- AI-Driven Efficiency: Systems like Tyvok S1’s vision tracking cut material inspection time by 60% .

- Green Standards: EU regulations mandate CE-certified fume filtration—enclosed models like Brand S1 and Tyvok S1 comply.

- Software Ecosystems: LightBurn compatibility (Tyvok) unlocks professional-grade design tools .

3. Pitfalls to Avoid

- "More Power = Better Cuts": A 20W diode outperforms a 40W CO₂ on 10mm oak due to wavelength efficiency.

- "Bigger Bed = Always Better": A 1.5m bed is essential for commercial work but impractical for hobbyists.

- Ignoring Software Limitations: Basic software restricts creativity—prioritize LightBurn or Xtool Creative Space .

Craftsmanship Meets Innovation

The 2025 landscape of wood laser cutters & engravers demands machines that respect the material’s natural beauty while delivering industrial-grade precision. Whether you’re chasing gallery-worthy details (Brand S1), scaling production (Brand Cloud 50W), or revolutionizing large-scale projects (Tyvok S1), these tools bridge artistry and technology.

Pro Tip: Test your machine’s parameters with sample wood scraps before committing to a project. Adjust power, speed, and airflow based on grain direction and density to achieve optimal results.

Choose a tool that amplifies your vision—not just your workflow—and let every cut honor the legacy of woodworking.