In the world of digital fabrication, laser cutters have become indispensable tools for creators, entrepreneurs, and educators. Over the past decade, many beginners started their journey with diode lasers—compact, affordable, and simple to use. But as their needs grew, more and more users began to upgrade their laser cutters, choosing powerful CO₂ systems for better speed, cutting depth, and material versatility.

This blog takes a deep dive into the CO₂ Laser vs Diode Laser discussion. We’ll break down the technical differences, highlight the unique advantages of the TYVOK K1 Series CO₂ Laser Cutter, and share real-world stories from Etsy shop owners, advertising sign makers, and schools.

1. Diode vs CO₂ Lasers: Understanding the Technology

1.1 Laser Wavelength and Material Absorption

Diode lasers emit blue light at around 450 nm. Materials like clear or light-colored acrylics, glass, or light plastics barely absorb this wavelength. Result: the beam passes through, leaving little effect.

CO₂ lasers, on the other hand, produce infrared light at 10.6 µm, which most non-metals absorb very efficiently. Result: strong heating, clean cutting, and the ability to process transparent acrylic, glass, and thick organic materials. Illustration comparing absorption rates of acrylic under diode vs CO₂ laser beams

Illustration comparing absorption rates of acrylic under diode vs CO₂ laser beams

1.2 Power and Cutting Speed

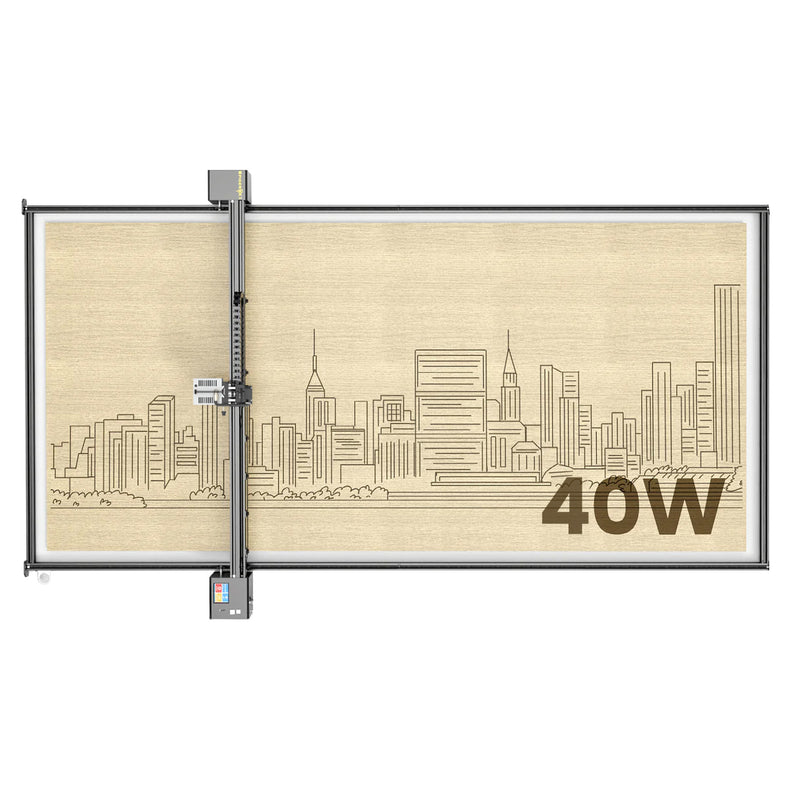

Diode lasers are typically 5–20 W, with advanced models reaching 40 W by combining multiple diodes.

Desktop CO₂ systems like the TYVOK K1 Pro deliver a true 100 W optical power, capable of cutting 20 mm solid wood or acrylic in a single pass.

Case comparison:

- A 24 W diode laser cutting 6 mm plywood might crawl at 250 mm/min.

- A 100 W CO₂ laser can do the same job at several inches per second, completing in a fraction of the time.

1.3 Work Area and Project Scale

Diode lasers are compact, open-frame machines, usually limited to 200–400 mm work areas.

The TYVOK K1 Series offers bed sizes up to 1200×2000 mm (4×8 ft), letting you engrave or cut full sheets without repositioning.

This difference is crucial for advertising signs, furniture panels, and exhibition displays.

TYVOK K1 cutting a large acrylic signage panel

TYVOK K1 cutting a large acrylic signage panel

1.4 Maintenance and Lifetime

Diode lasers: long lifespan (30,000–50,000 hours), almost no maintenance.

CO₂ lasers: glass tubes typically last 5,000–8,000 hours, require water cooling and occasional mirror alignment.

Yes, maintenance is higher—but the professional-grade performance pays off in production speed, finish quality, and business growth.

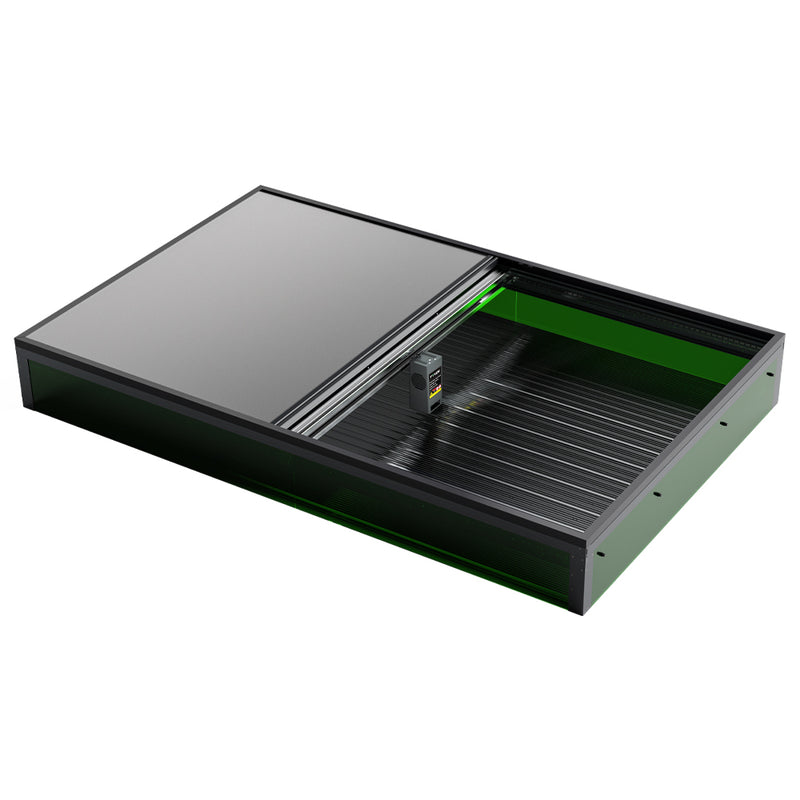

2. The TYVOK K1 Series: Industrial Power, Maker-Friendly Design

The TYVOK K1 Series CO₂ Laser Cutter bridges the gap between hobbyist machines and industrial systems. It was built to give makers, small business owners, and educators access to industrial-grade tools at a more approachable cost.

Key Features:

- 100 W True CO₂ Power – Cuts 20 mm wood/acrylic in one pass.

- Massive Bed Sizes – From 1200×700 mm up to 1200×2000 mm.

- High-Speed Motion Control – Up to 1000 mm/s engraving with ±0.05 mm repeat accuracy.

- Smart Smoke & Dust Control – Built-in dual airflow system.

- Integrated Water Cooling – Stable tube temperature.

- Ease of Use – Autofocus, HD camera, 5” touchscreen.

- Software Flexibility – Works with LightBurn, RDWorks.

- Safety First – Enclosed design, auto-pause, protective viewing window.

3. Case Studies: Why Users Upgrade from Diode to CO₂

3.1 Etsy Sellers: Scaling Handmade Businesses

Many Etsy shop owners begin with a diode laser for small-batch items. But growth quickly hits limits:

- Long cutting times on thicker wood

- Inability to process transparent acrylic or glass

- Small work areas unsuitable for bulk orders

After upgrading to CO₂ (like the TYVOK K1):

- Production speed doubles or triples

- New product lines (clear acrylic jewelry, glass engraving, bamboo boards)

- Higher sales & customer retention

Real example: An Etsy seller in Texas scaled from $2,000/month to $7,500/month in sales after switching to a 100 W CO₂.

3.2 Advertising Sign Makers: Industrial-Level Needs

Sign makers and advertising agencies require fast, flawless acrylic cutting for storefront letters and logos.

With diode lasers:

- Multiple passes needed for thicker acrylic

- Edges often rough, requiring post-processing

With CO₂ lasers:

- Smooth, polished edges

- Complex shapes with no hand finishing

- Entire signage sheets processed in one go

Real example: A signage shop in California upgraded from diode to 100 W CO₂.

- Before: 10 sets of channel letters/day

- After: 30 sets/day

- Result: 40% revenue increase within 6 months

3.3 Education & Maker Spaces: Creativity Without Limits

Schools and maker labs are embracing CO₂ systems for project-based learning and entrepreneurship training.

STEM Projects: Robotics parts, physics kits, architectural models

Arts & Crafts: Puzzles, trophies, campus branding

Entrepreneurship: Students making bookmarks, keychains, decorations for fairs

Real example: A high school FabLab in Florida introduced a CO₂ laser. Students launched a 'Makers Market' selling $5 engraved keychains, funding more lab equipment.

4. Why Upgrade? The Core Benefits

Upgrading from diode to CO₂ isn’t just a technical step—it’s a business and creative decision:

1. Speed – Faster throughput for bulk orders

2. Material Versatility – Wood, acrylic, glass, fabric, leather

3. Larger Projects – Beds up to 1200×2000 mm

4. Professional Finish – Smooth edges and deep cuts

5. Business Growth – Higher production = higher income

5. Conclusion: The Light That Expands Creativity

For hobbyists, diode lasers are a great starting point. But as projects grow in size or ambition, the CO₂ laser becomes essential.

The TYVOK K1 Series CO₂ Laser Cutter delivers:

- Industrial-grade power

- Maker-friendly usability

- Versatility across education, business, and creative industries

From Etsy entrepreneurs scaling their sales, to sign makers producing flawless displays, to schools inspiring the next generation—CO₂ lasers open doors that diodes cannot.

Quote: 'I loved my diode laser. But when it came time to cut thicker materials and grow my business, the CO₂ became irreplaceable.'