Introduction: Boosting Efficiency with the Spider S1

Meet James, a small business owner passionate about personalized crafts. Initially, he struggled to meet bulk orders efficiently, often spending long hours with slow, inconsistent engraving processes. That all changed when he upgraded to the Tyvok Spider S1—a game-changer that revolutionized his production workflow. With its advanced features, multi-machine compatibility, and superior precision, James was able to scale up his business and fulfill large orders with ease.

If you, like James, want to increase your production efficiency while maintaining high-quality engravings, this guide will walk you through the essential steps to mass-engrave customized products using the Tyvok Spider S1.

Materials and Tools Preparation

To take full advantage of the Spider S1’s capabilities, you need the right materials. Here’s a list of materials that work best with the large engraving area:

-

Wood (e.g., plywood, bamboo, walnut, maple)

-

Leather (genuine and synthetic for wallets, belts, and keychains)

-

Metal (aluminum, stainless steel for nameplates and tags)

-

Acrylic & Plastics (for signage, decorative panels)

-

Glass & Ceramic (for customized drinkware and tiles)

Additionally, make sure you have:

-

A high-powered air assist system to keep the work surface clean

-

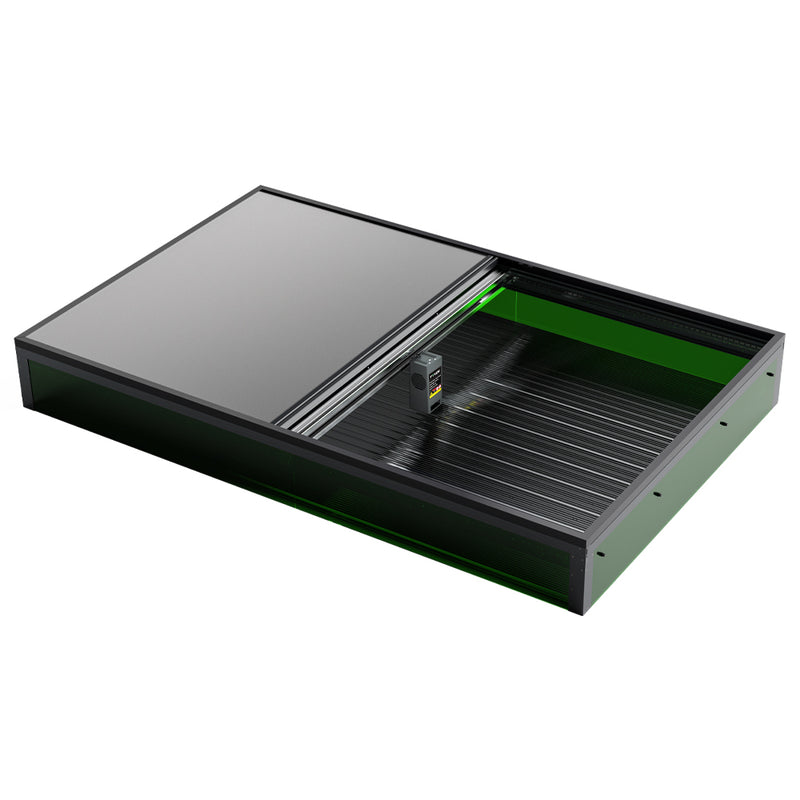

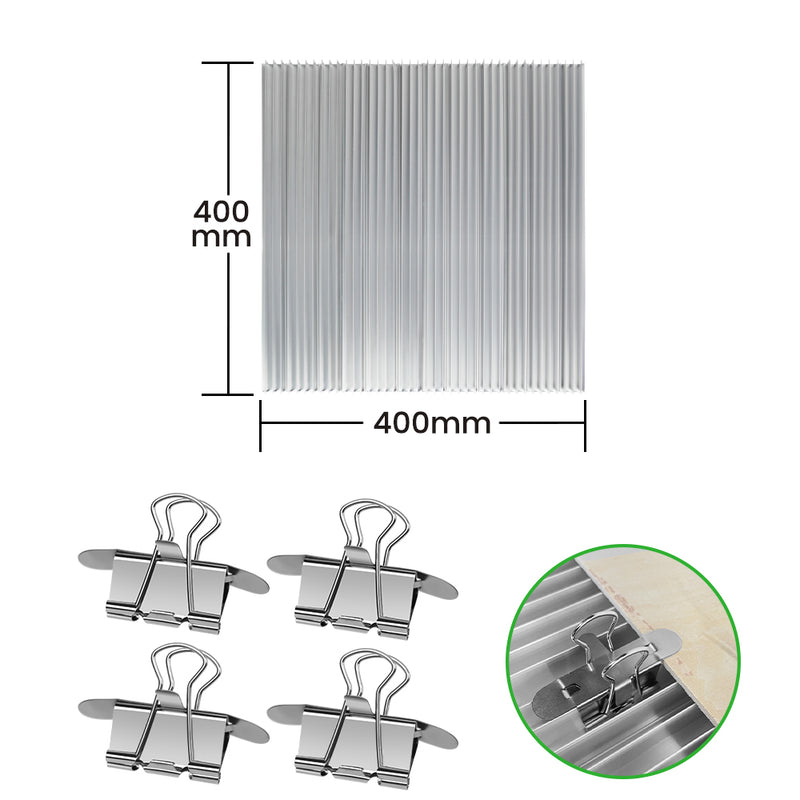

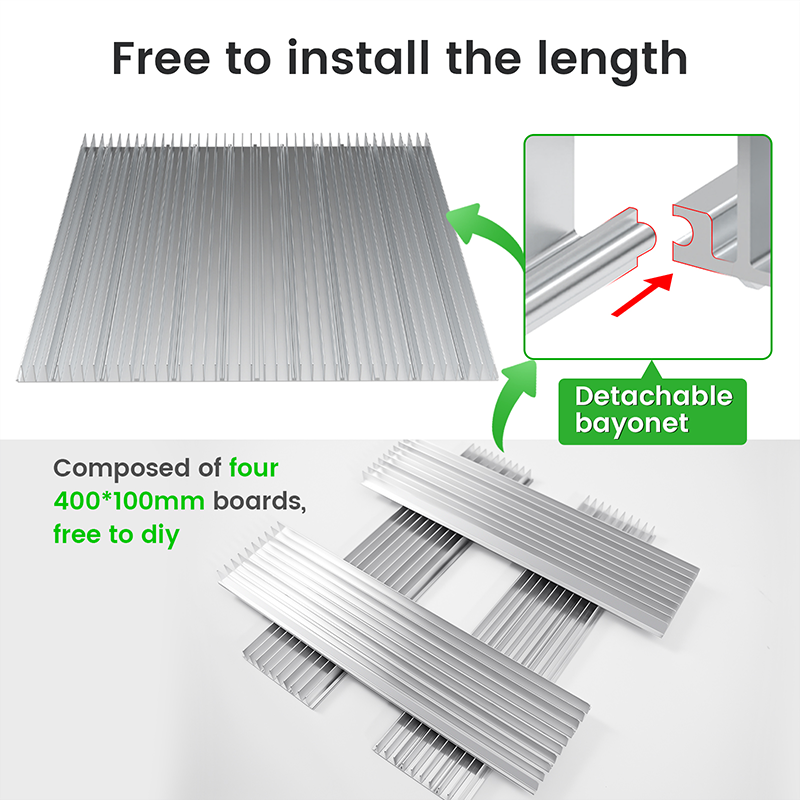

A honeycomb work bed for stable engraving

-

A proper exhaust or air filtration system to handle smoke and debris

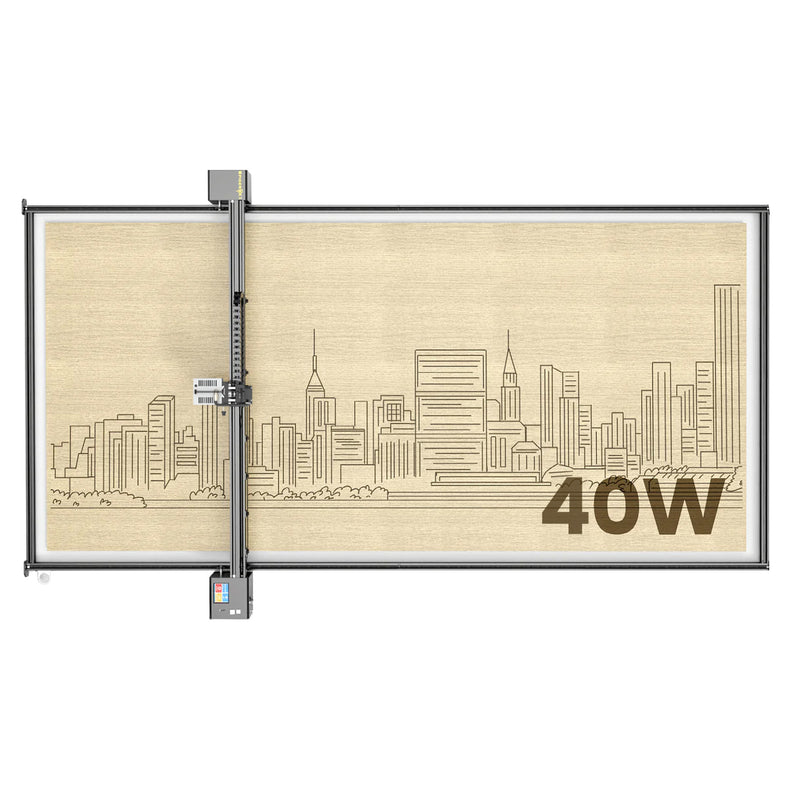

Multi-Machine Y-Axis Sharing: Enhancing Efficiency

One of the most impressive features of the Spider S1 is its ability to work in a synchronized multi-machine setup. Here’s how you can leverage this for large-scale production:

-

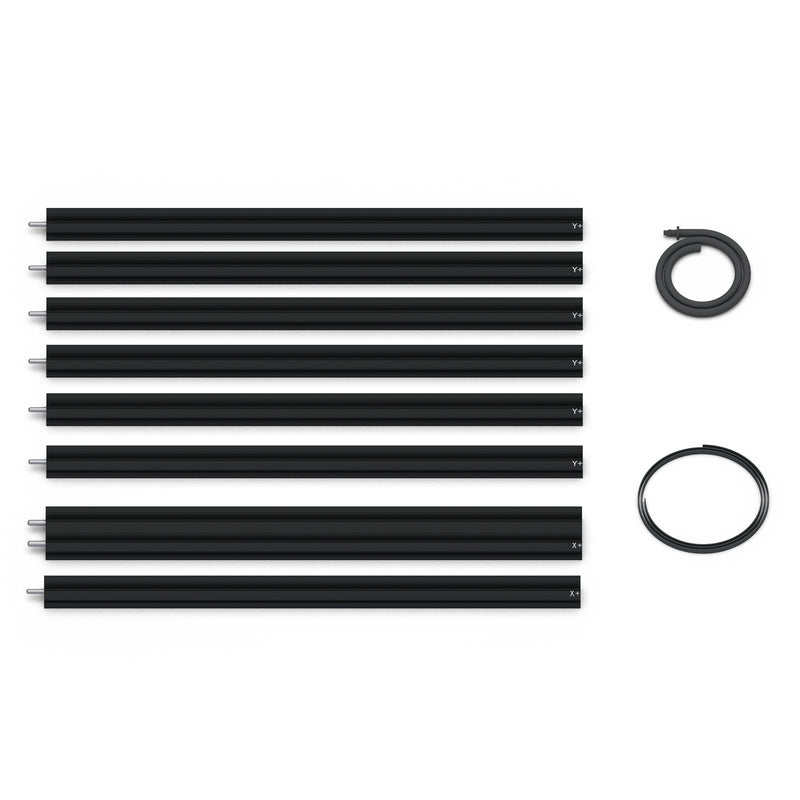

Connect Multiple Machines: The Y-axis can be shared across multiple Spider S1 units, allowing them to function in parallel.

-

Unified Job Execution: With proper alignment, the engravers can work simultaneously on different sections of the same project.

-

Boosting Production Output: By running multiple engravers at once, you can reduce processing time without sacrificing quality.

This feature makes it easier to scale up operations without manually handling each machine individually.

Detailed Engraving Workflow

To achieve high-precision, fast engravings, follow these optimized settings:

Step 1: Designing Your Project

-

Use LightBurn or LaserGRBL to prepare your engraving file.

-

Set up a batch layout in the software to maximize material use.

-

Use the array function in LightBurn to create multiple copies of the same design.

Step 2: Setting the Right Parameters

-

Power & Speed Optimization

-

Wood: 80% power, 500mm/min speed

-

Leather: 50% power, 600mm/min speed

-

Metal (with marking spray): 90% power, 300mm/min speed

-

-

Passes & Focus Adjustments

-

Use multiple passes for deep engraving.

-

Ensure the laser focus is perfectly aligned for precise results.

-

Step 3: Running the Engraving Job

-

Secure the material with clamps or magnets.

-

Enable air assist to minimize charring.

-

Monitor the process using the camera preview (if available).

-

For bulk jobs, use the multi-machine setup to engrave several pieces at once.

Optimization Tips

Once the engraving is complete, consider these finishing touches:

-

Polishing: Use fine-grit sandpaper for wood and a microfiber cloth for metal.

-

Color Filling: Apply acrylic paint or resin for enhanced contrast.

-

Sealing & Protection: Use a protective spray or wax for durability.

-

Batch Sorting: Label and categorize your engraved items for seamless order fulfillment.

Conclusion: The Business Value of the Spider S1

The Tyvok Spider S1 isn’t just a laser engraver—it’s a powerful tool for scaling up your business. With its multi-machine capabilities, efficient workflow, and high-precision output, businesses can now mass-produce customized items faster and more efficiently than ever.

If you’re looking to boost your engraving production, the Spider S1 is the perfect investment for businesses, entrepreneurs, and makers who want to take their craft to the next level.

Are you ready to scale up your laser engraving business? Get started today with the Tyvok Spider S1 and experience the future of mass customization!