Why is it a “Historic Breakthrough”?

For a long time, a 100W CO₂ laser cutter meant:

- Expensive: usually $7,000–$15,000.

- Bulky: almost impossible to place in a home or studio.

- Complicated installation: required engineers to align optics.

- Off-limits for homes and classrooms.

Most makers, Etsy sellers, small factories, and schools were stuck between two choices:

- Buy a desktop 40W/60W laser: cheaper, but can’t cut thick material.

- Outsource production: costly, slow, and dependent on others.

The Tyvok K1 finally changes this reality:

- Starts at just $2,299, far cheaper than industrial machines.

- Modular design: fits through any 300mm doorway.

- Pre-aligned and sealed optics: no manual adjustments needed.

- Modular expansion: upgrade bed size as your business grows.

For the first time, 100W industrial power is accessible in homes, studios, and classrooms.

Core Product Highlights

-

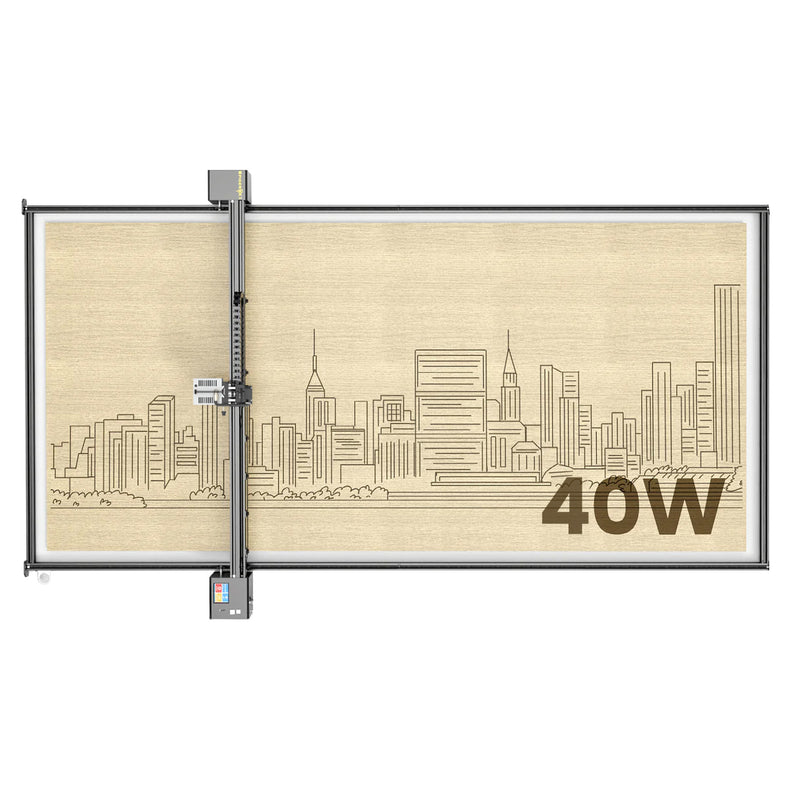

100W Industrial Power: Cuts through 20mm acrylic or wood in one pass, with speeds up to 1000mm/s and ±0.05mm accuracy.

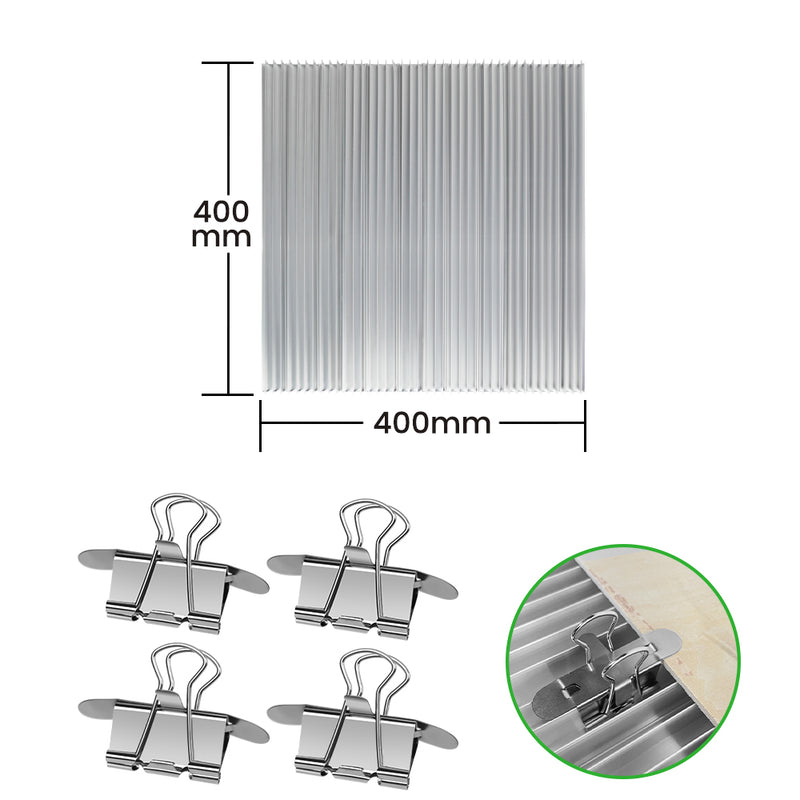

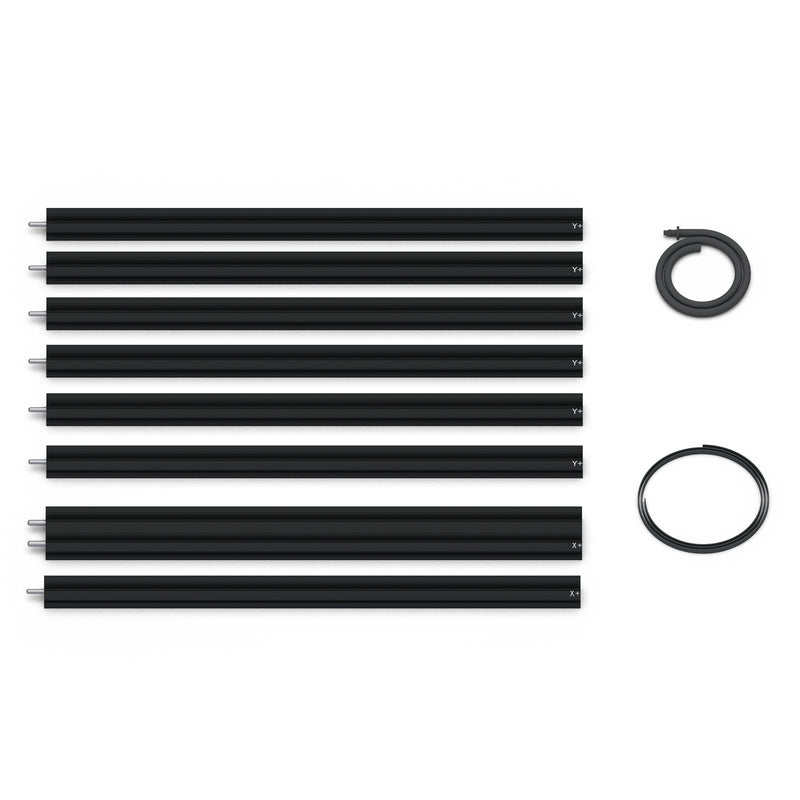

- Modular, Split Design: Transport X and Y axes separately, upgrade Y-axis from 1200×700mm to 2000mm+.

- No Optics Alignment: Factory-sealed optical path eliminates mirror adjustments.

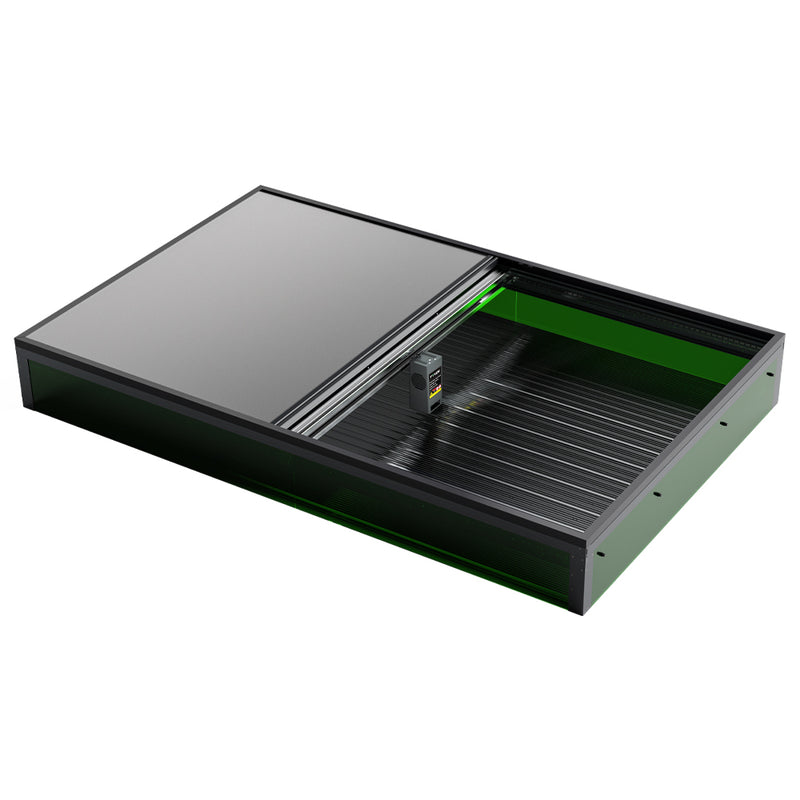

- Home-Friendly Dual exhaust system, optional enclosure, anti-freeze water cooling.

- Software Compatible: Tyvok Studio, RDWorks, and fully supports LightBurn

The User’s Ledger: Saving and Earning

|

User Type |

Common Need |

Outsourcing/Other Solution |

With Tyvok K1 |

ROI |

|

Advertising Company |

Cutting 10–20mm acrylic signage |

$30–50 per sheet, $200+ for 2m signage |

Raw material $20, self-cut in 1 hour |

Save $150 per job; $15,000/year on 100 jobs |

|

Etsy Seller |

Batch wood or leather cutting |

40W desktop can’t cut thick, often outsource |

Cuts 12–20mm wood directly, 2–3× faster |

At $3,000 monthly sales, 50% faster = $18,000 extra yearly |

|

Education / Makerspace |

Courses, student projects |

Industrial machines $10k+, not classroom-friendly |

$2,299, fits through 300mm door, LightBurn compatible |

Extra courses, recoup in 1 semester |

|

Small Factory |

Sample prototyping |

$100–300 per outsourced prototype |

Only material cost, cut in-house |

10 samples/month = $12,000+ savings yearly |

Competition Comparison

|

Brand/Model |

Power |

Price |

Strengths |

Limitations |

|

Glowforge Pro |

45W |

$4499+ |

Easy to use, cloud-based |

Weak power, can’t cut thick materials |

|

OMTech AF2440-100 |

100W |

$4000–6000 |

High value |

Bulky, needs alignment, not home-friendly |

|

xTool P3 |

80W |

$5999 |

Smart automation |

Lower power, higher price |

|

Thunder Nova 24 |

100W |

$7000+ |

Industrial stability |

Over budget, hard to move |

|

Tyvok K1 |

100W |

$2499+ |

Modular, home-friendly, no alignment, upgradable |

New brand, less recognition |

Future Potential: A Growth Partner for Users

-

Etsy Sellers: Start with small art, then scale to large orders—no need for a new machine, just extend the bed.

- Advertising Companies: Capture more contracts, ROI cycle shortened to weeks.

- Educational Institutions: Affordable access to industrial power, makes classes more competitive.

- Small Factory Owners: Use it to test markets without massive upfront investment.

Tyvok K1 is not a one-time purchase—it’s a platform. With upgradeable modules, accessories, and continuous software updates, it evolves with the user. Instead of buying a fixed tool, you are investing in a growth path.

Conclusion

If you are considering a laser cutter, ask yourself:

1. Are you tired of high outsourcing costs?

2. Do you want to finish jobs faster and keep more orders in-house?

3. Do you want a machine that grows with your business instead of forcing you to repurchase?

If the answer is yes, then Tyvok K1 may be exactly the machine you’ve been waiting for. It’s not just about putting a 100W industrial laser in your room—it’s about giving creators, small businesses, and schools a real chance to step into the future of making.